VANCOUVER, BC / ACCESS Newswire / July 2, 2025 / Aton Resources Inc. (TSXV:AAN) ("Aton" or the "Company") updates investors on the results of its phase 3 reverse circulation percussion ("RC") drilling programme at the Semna gold mine project, located within the retained exploration areas of the Company's Abu Marawat Concession ("Abu Marawat" or the "Concession") in the Eastern Desert of Egypt.

Highlights:

44 RC drill holes (SMP-049 to SMP-092) have been drilled in the current programme to date at Semna, for a total of 5,257m. Full assay results, including conventional fire assay and metallic screen fire assay results, are now available for the first 25 holes of the programme (SMP-049 to SMP-073);

Significant high grade mineralised intersections (based on screen fire assay analyses), returned to date, include the following:

14.33 g/t Au over a 9m interval, from 72m downhole depth, from hole SMP-050, including intervals of 46.50 g/t Au over 1m and 26.11 g/t Au over 3m;

5.41 g/t Au over a 14m interval, from 39m downhole depth, including an interval of 22.57m g/t Au over 3m (hole SMP-056);

10.74 g/t Au over a 6m interval, from 138m downhole depth (hole SMP-073);

8.66 g/t Au over a 7m interval, from 44m downhole depth, including an interval of 21.73m g/t Au over 2m (hole SMP-052);

10.06 g/t Au over a 3m interval, from 125m downhole depth (hole SMP-071);

6.16 g/t Au over a 6m interval, from 38m downhole depth (hole SMP-053).

"This latest set of very positive drilling results continues on from the previous programmes, further confirming the presence and persistence of the high grade veins at Semna, and we are really very happy with them" said Tonno Vahk, CEO. "We are currently pushing ahead at full speed with the objective of being able to include the Semna and Abu Marawat deposits in the PFS that we commenced last year, as Aton continues to work steadily towards its objective of developing multiple mining operations on the Abu Marawat Concession. We have also now completed the diamond drilling programme at Abu Marawat, and the rig will be mobilising to Hamama in the coming days to start on a short geotechnical and metallurgical drilling programme. We have temporarily suspended the RC drilling at Semna, with the rig also having been moved to Hamama to drill groundwater wells, as part of the vitally important programme to develop a process water supply for the projects. We plan to be back both RC and diamond drilling at Semna again within the next 2 months to continue on from the success of these latest results, and we will also be kicking off a follow-up RC drilling programme at Abu Marawat within the next 4 weeks."

Semna gold mine project

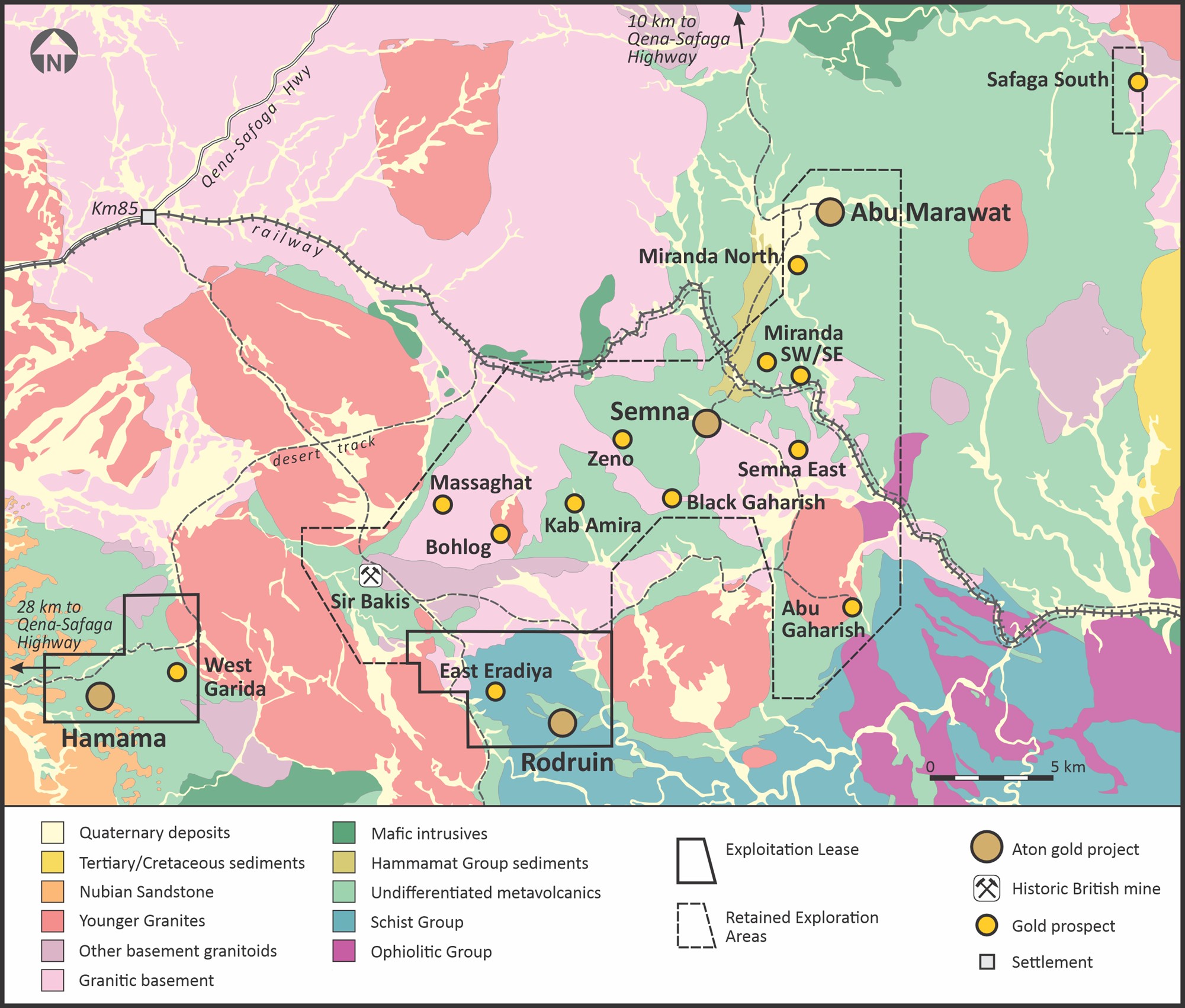

The Semna prospect is located approximately 27km east-northeast of the Hamama West deposit and 13km north-northeast of the Rodruin deposit, and is accessed via desert tracks from either Hamama, Rodruin or the Abu Marawat deposit to the north (Figure 1). The Semna area has a long history of gold mining, dating back thousands of years to the Old Kingdom, and it was more recently exploited between 1904 and 1906 by two British companies, which worked the Main Vein on two underground levels. It is anecdotally suggested that the Semna mine had the widest vein exploited during the early 20th Century phase of gold mining in Egypt, reaching up to 6m width in places, with the British companies reporting mining grades of over 2 ounces per ton. Reports from the British Mining Journal from 1905 indicated that some remnant pillars within the ancient Pharaonic-era stopes assayed up to 5.5 ounces per ton of gold. More recently the area has been extensively worked by illegal artisanal miners, who have now been removed from the site.

Figure 1: Geology plan of the Abu Marawat Concession, showing the location of the Semna prospect

During 2023 Aton completed a first phase of RC drilling at Semna, drilling 21 holes for a total of 3,662 metres. This initial programme yielded excellent results with mineralised intersections including 50.07 g/t Au over a 6m interval (hole SMP-016), 28.36 g/t Au over a 4m interval (hole SMP-003), 10.61 g/t Au over a 9m interval (hole SMP-019), and 5.73 g/t Au over a 14m interval (hole SMP-017). The RC drilling confirmed the presence of significant coarse gold in the Semna mineralisation (see news release dated December 18, 2023).

Subsequent metallurgical testwork undertaken by Aton returned very positive results with gold recoveries in excess of 97% from 2 representative bulk samples of the Semna mineralisation. Gold was also recovered to 2 gravity concentrates at rates of 56.4% and 62.2%, again indicating a significant component of coarse gold in the Semna mineralisation. The testwork indicated that the Semna mineralisation is amenable to treatment by both conventional CIL, and gravity concentration-leach processing options (see news release dated January 4, 2024).

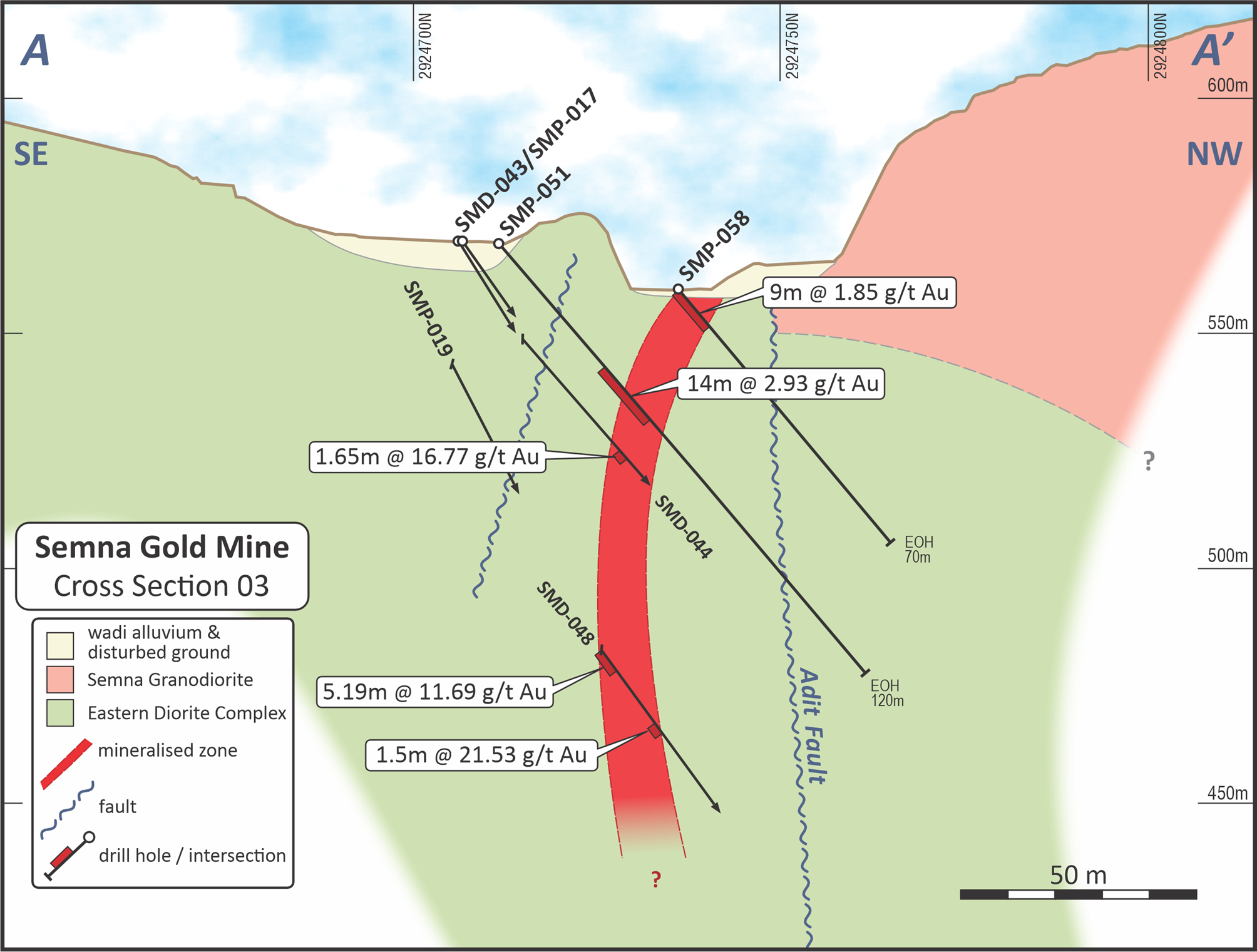

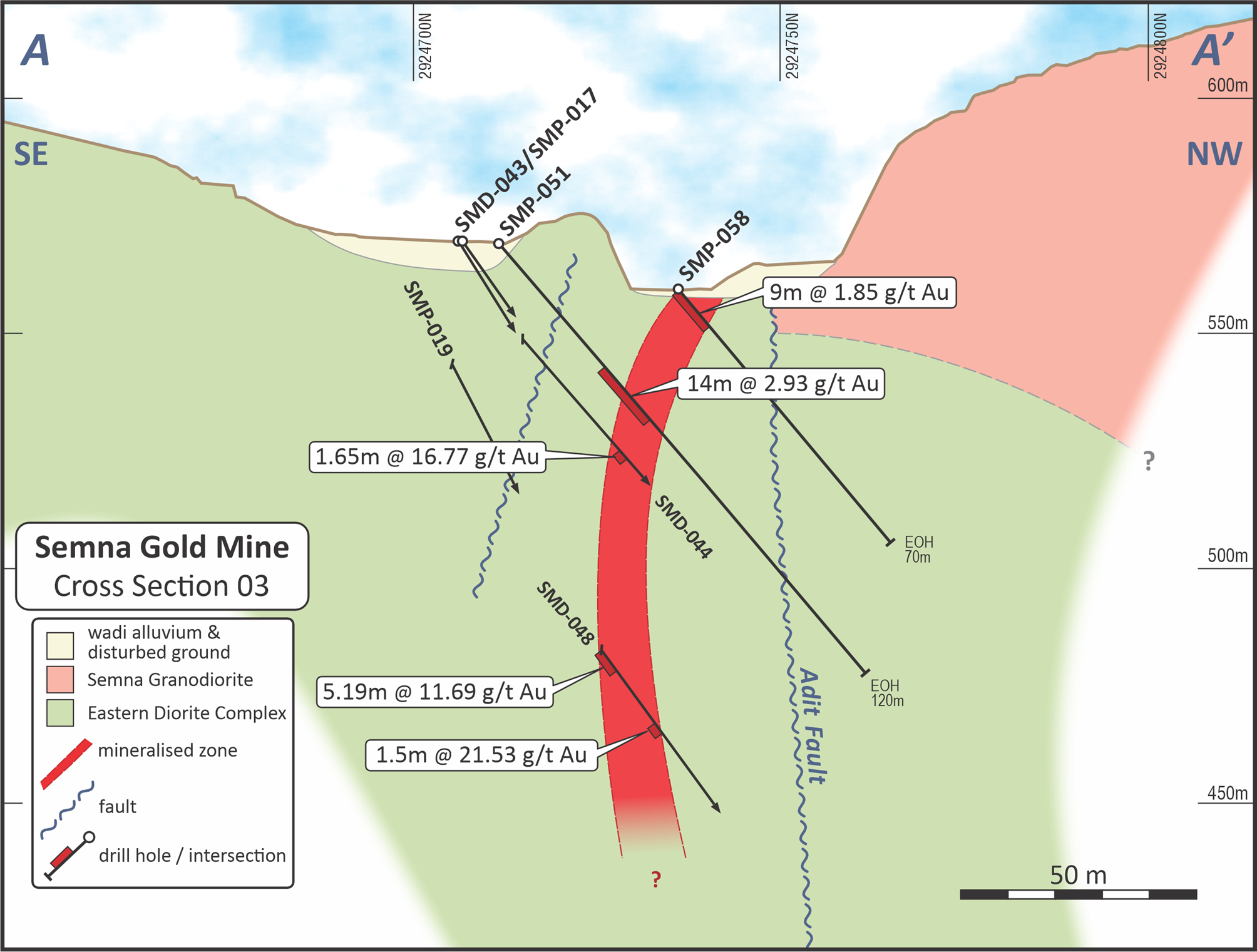

In 2024 the Company completed a 27 hole follow up diamond drilling programme for a total of 4,701 metres drilled (see news release dated July 4, 2024). This programme also returned significant high grade intersections including 11.69 g/t Au over a 5.19m interval, from 126.35m downhole depth, and 21.53 g/t Au over a 1.50m interval, from 147.20m (both from hole SMD-048), 15.05 g/t Auover a 2.55m interval, from 100.45m (hole SMD-025), 27.90 g/t Au over a 1.37m interval, from 68.94m (hole SMD-043), 8.10 g/t Au over a 3.13m mineral, from 135.83m (hole SMD-027), and 16.77 g/t Au over a 1.55m interval, from 64.30m (hole SMD-044).

The mineralisation at Semna is interpreted as being orogenic in style, and is associated with an array of structures, presumed to have formed in dilational zones, accompanied by shearing and weak to moderate phyllic wall rock alteration. The mineralised structures appear to be localised between and offset by a series of regional north-northeast striking faults. These structures are frequently manifested as milky white quartz veins, which apparently anastomose and pinch and swell, and are associated with locally strong phyllic wall rock alteration. The quartz veins are variably sulphidic, and the highest grades of gold mineralisation are typically associated with lenses and selvages of sulphide minerals, sub-parallel to the veins, as well as occurring at the margins of the veins, and in the immediately adjacent altered wall rocks. The mineralisation at Semna predominantly consists only of gold, which is often coarse and nuggety. The sheared veins locally contain abundant chalcopyrite, and can carry significantly elevated grades of silver and copper.

Figure 2: Remnant rib pillar of theMain Vein in the underground workings, showing lenses and ribbons of vein-parallel sulphidic material (*)

Semna phase 3 RC drilling programme

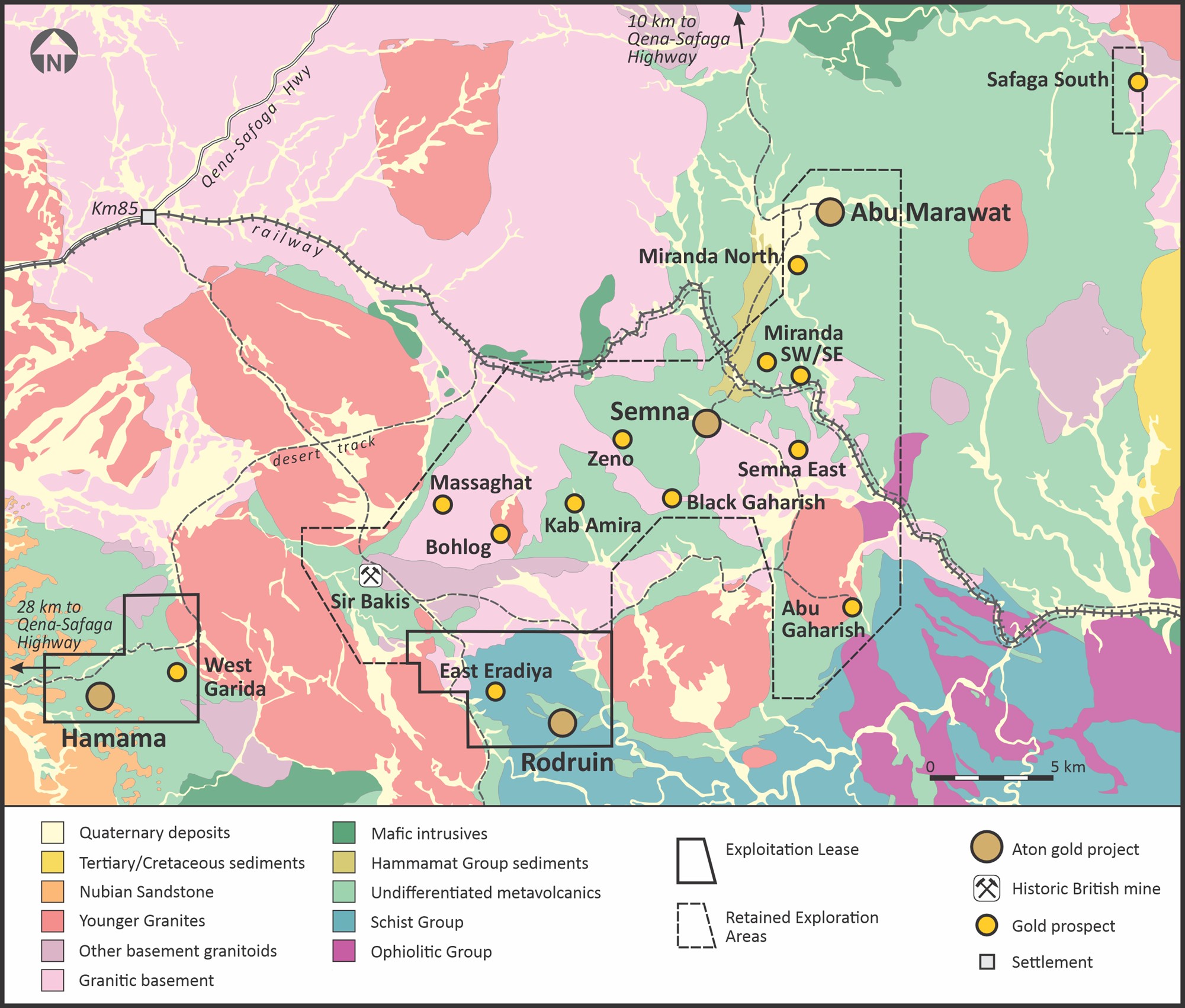

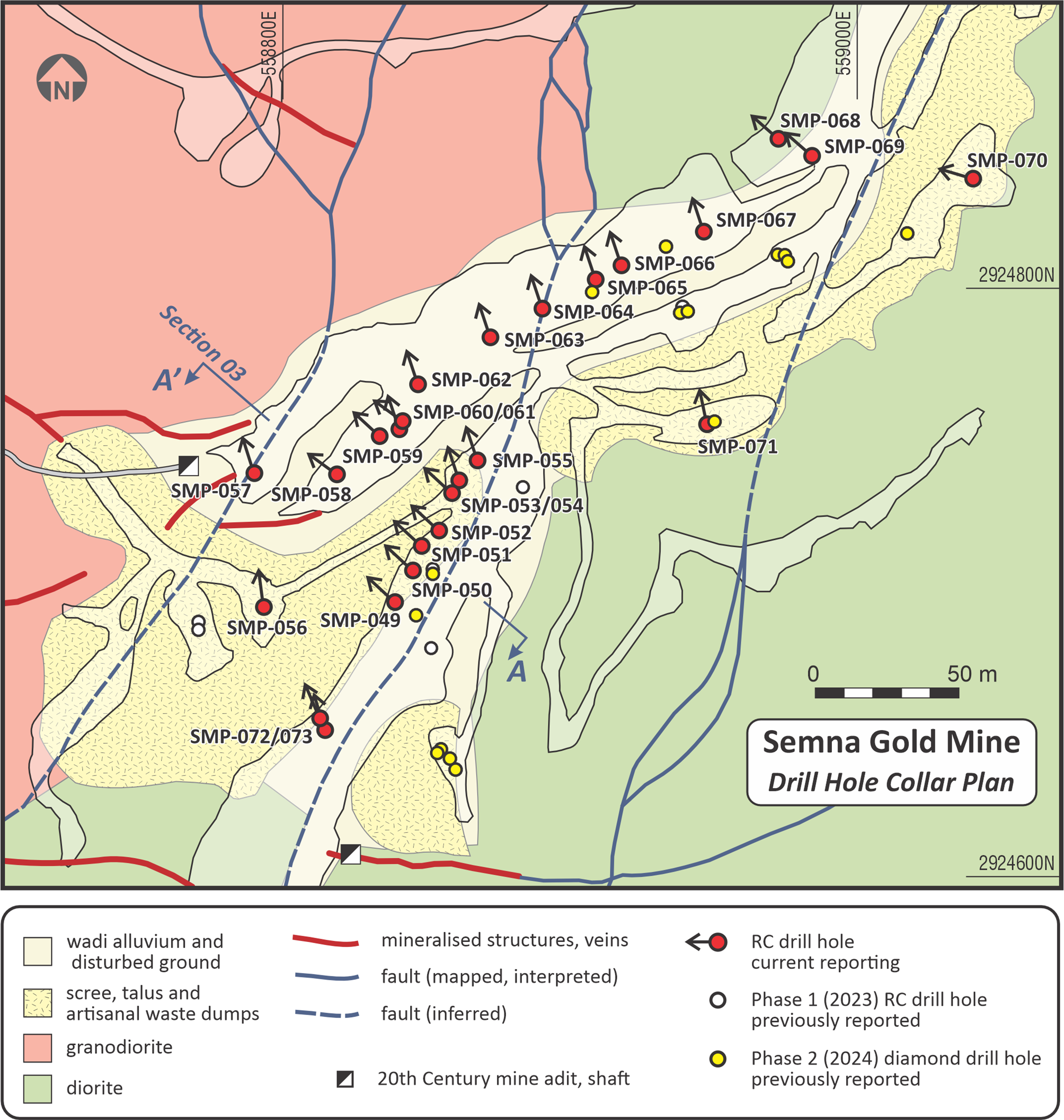

To date 44 RC drill holes (SMP-049 to SMP-092) have been drilled in the current programme, for a total of 5,257 metres (Figure 3). The current phase 3 Semna RC programme has been temporarily suspended, as the RC rig has been moved to Hamama for other priority work on the Hamama Pre-Feasibility Study. Once this is completed the rig will carry out a c. 5,000m programme of RC drilling at Abu Marawat, before returning to Semna.

The phase 3 RC drilling has initially been undertaken on a reasonably tight spacing as the Company looks to accelerate the estimation of a maiden resource at Semna, while considering the grade variability and the irregular distribution of the nuggety coarse gold in the pinching and swelling veins, as well as continuing to test the eastern and depth extensions of the identified mineralisation. Full collar details of all holes are provided in Appendix A.

Samples were initially composited over 4m intervals, with the entire length of all the drill holes being submitted for gold fire assay analysis. Selected 1m split samples collected directly during the drilling were subsequently submitted for additional gold fire assay analysis, as well as for silver and copper analysis, after the receipt of the 4m composite assay results. After receipt of the 1m split assay results a further 165 selected 1m splits from the drilling were also submitted for metallic screen fire assay analysis, comprising most of the samples from within the mineralised intervals.

Figure 3: Geology and drill hole collar plan of the Semna prospect, SMP-049 to SMP-073

Discussion of results

Selected mineralised intersections from holes SMP-049 to SMP-073 are shown below in Table 1. Full mineralised intersection details from SMP-049 to SMP-073 are provided in Appendices B, C, and D (based on screen fire assay analyses, conventional fire assay analyses from the 1m split samples, and conventional fire assay analyses from the 4m composite samples, respectively).

Hole ID | Intersection (m) | Au 1 (g/t) | Ag (g/t) | Cu (ppm) | Comments | ||

From | To | Interval | |||||

SMP-050 | 72 | 81 | 9 | 14.33 | 2.2 | 29 | Fire assay: 9m @ 13.39 g/t Au |

incl. | 75 | 76 | 1 | 46.50 | 6.7 | 62 | |

and incl. | 75 | 78 | 3 | 26.11 | 3.6 | 26 | |

SMP-051 | 35 | 49 | 14 | 2.93 | 0.7 | 68 | Fire assay: 14m @ 2.60 g/t Au |

incl. | 44 | 49 | 5 | 7.65 | 1.7 | 73 | |

SMP-052 | 44 | 51 | 7 | 8.66 | 1.4 | 19 | Fire assay: 7m @ 10.52 g/t Au |

incl. | 49 | 51 | 2 | 21.73 | 3.9 | 23 | |

SMP-053 | 38 | 44 | 6 | 6.16 | 0.8 | 39 | Fire assay: 6m @ 7.79 g/t Au |

SMP-056 | 39 | 53 | 14 | 5.41 | 1.1 | 39 | Fire assay: 14m @ 6.97 g/t Au |

incl. | 50 | 53 | 3 | 22.57 | 4.3 | 36 | |

SMP-058 | 1 | 10 | 9 | 1.85 | 0.3 | 338 | Fire assay: 9m @ 1.92 g/t Au |

incl. | 5 | 6 | 1 | 11.65 | 0.6 | 242 | |

SMP-066 | 30 | 40 | 10 | 1.99 | 2.9 | 158 | Fire assay: 10m @ 2.11 g/t Au |

SMP-069 | 77 | 81 | 4 | 3.98 | 3.3 | 2,097 | Fire assay: 4m @ 5.33 g/t Au |

SMP-071 | 125 | 128 | 3 | 10.06 | 0.8 | 22 | Fire assay: 3m @ 5.14 g/t Au |

incl. | 125 | 126 | 1 | 29.10 | 2.1 | 34 | |

SMP-073 | 138 | 144 | 6 | 10.74 | 1.9 | 16 | Fire assay: 6m @ 12.29 g/t Au |

incl. | 138 | 139 | 1 | 35.20 | 6.7 | 55 | |

Notes:

| |||||||

Table 1: Selected final intersections from the Semna phase 3 RC drilling, SMP-049 to SMP-073

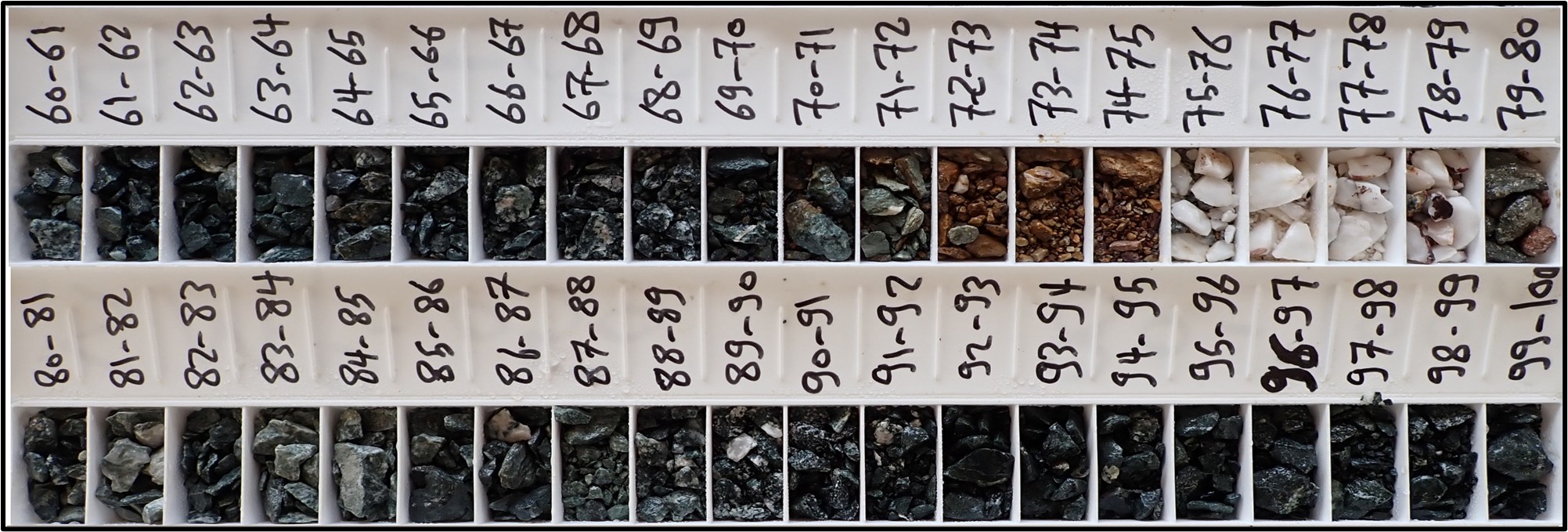

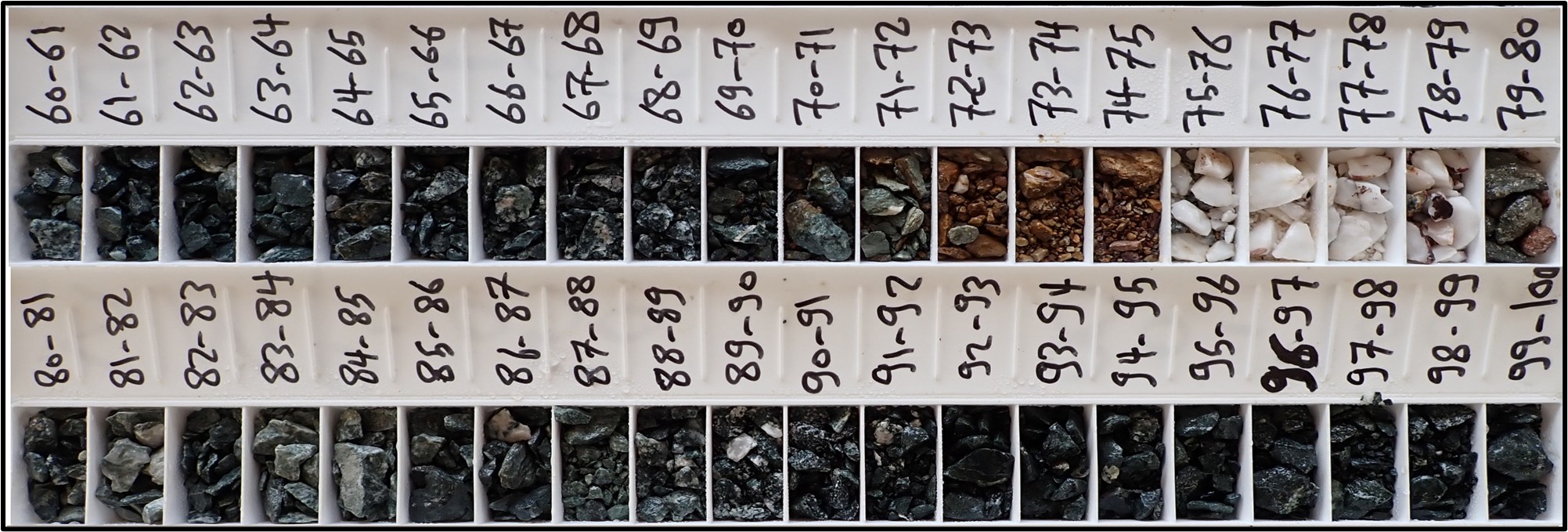

Figure 4: RC percussion chips from hole SMP-050, 60-100m depth, showing the mineralised interval between 72-81m, associated with a massive white quartz vein

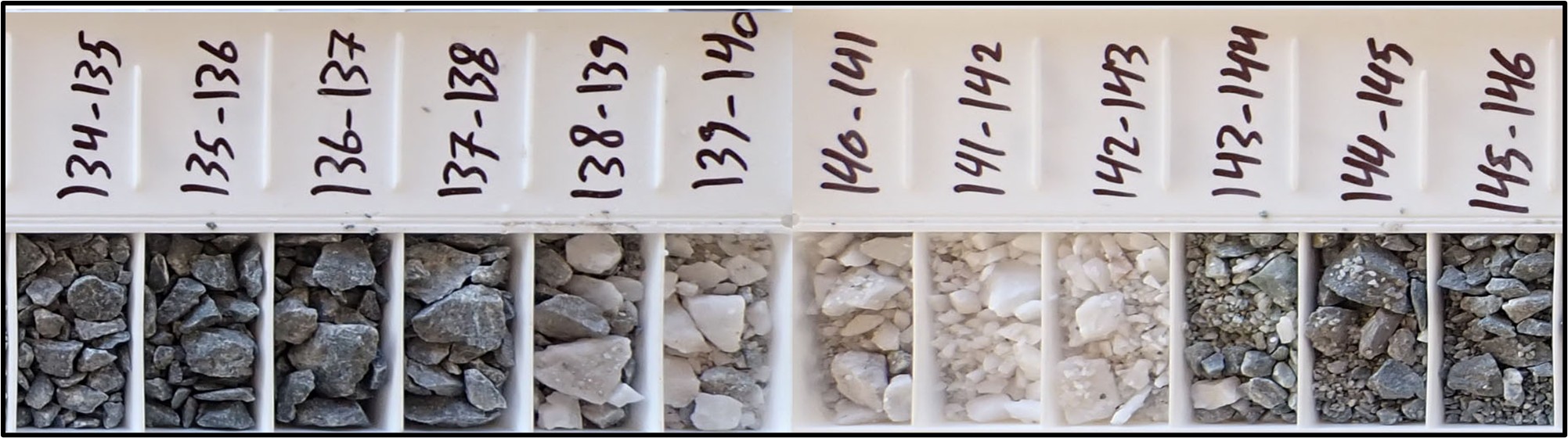

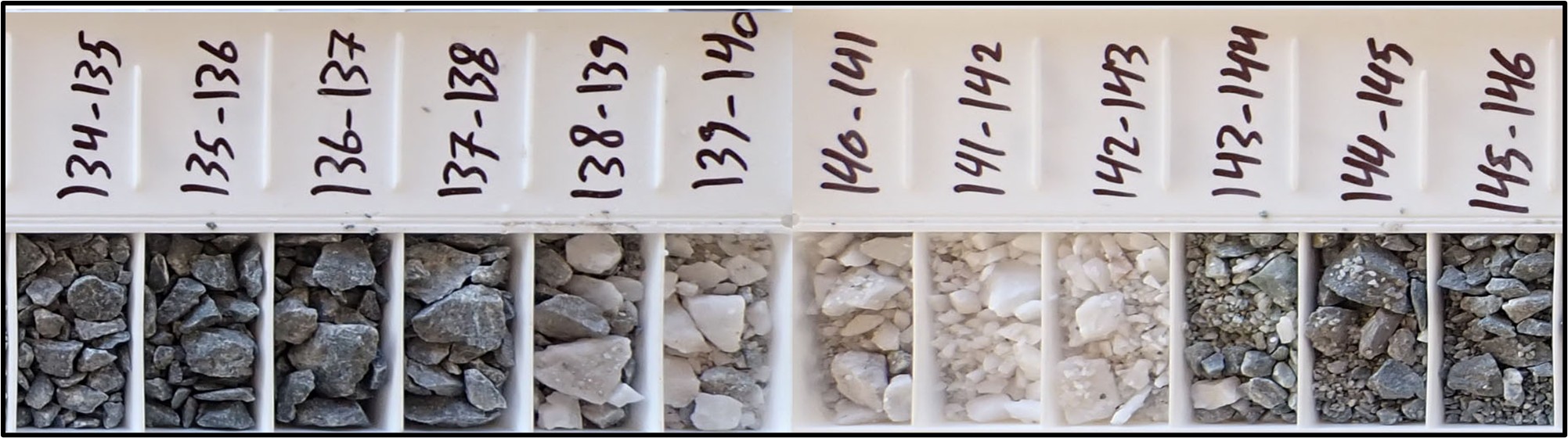

The latest phase of RC drilling continues to indicate that the gold mineralisation is usually associated with the milky white quartz veins, with gold appearing to be distributed both within the quartz veins themselves, but usually at lower grades, and typically also at higher grades in the sulphide-bearing margins and wall rock adjacent to the veins, as was mapped in the underground workings (Figures 2, 4 above and 5 below). Note that in hole SMP-050 (Figure 4) the highest grades returned come from the immediate margins of the quartz vein: 45.6 g/t Au between 75-76m and 61.8 g/t Au between 79-80m. The same is noted in hole SMP-073 (Figure 5), with the highest grades also returned from margins of the quartz vein: 35.2 g/t Au between 138-139m and 13.5 g/t Au between 142-143m.

Figure 5: RC percussion chips from hole SMP-073, 134-146m depth, showing the mineralised interval between 138-144m, also associated with a massive white quartz vein

The quartz veins themselves can be either virtually barren or weakly mineralised (eg. SMP-050: 0.30 g/t Au between 76-78m, see Figure 4), or well mineralised (eg. SMP-073: 6.85 g/t Au between 140-142m, see Figure 5). However there does appear to be a fairly clear correlation between the gold grades and the quantity of sulphide present in the veins themselves, and on their margins.

Figure 6: Cross-section O3 through the eastern extension of the Semna deposit (refer to Figure 2 for location)

The latest phase of drilling continues to indicate the presence of a sub-vertical zone of multiple quartz veins in the area tested, which appear to be largely sub-parallel, over a true width of approximately 20m (Figure 6). There is also increasing evidence from the drilling of the presence of a series of well mineralised "flat" easterly-dipping structures, as mapped at surface in channel sample profile SMC-065, which returned a mineralised interval at surface of 2.60 g/t Au over 39.3 metres (see news release dated February 1, 2024). Surface mapping and evidence from drill holes suggest that the "flat-dipping" veins to be quite narrow, in contrast to the steep milky quartz veins, which reach several metres in width. The "flat-dipping" veins rarely exceed 10-20cm in width individually, but numerous stacked tension gash style veins occur in these structural zones. Anecdotally these "flat-dipping" vein arrays appear to be associated with elevated copper grades.

Sampling methodology and analysis

Please also refer to the "Sampling and analytical procedures" section below for fuller details of these procedures.

The drilling was undertaken by Capital Limited, using an Explorac 100 RC drilling rig with an onboard cone splitter. The onboard splitter was set to produce 2 sub-samples of the chips ("L" and "R" samples, collected in cloth bags) each representing c. 12.5% of the entire sample over a metre interval. The remaining c. 75% of the sample was collected in bulk plastic bags at the rig. Sampling of each and every hole was undertaken in their entirety at 1 metre intervals.

Hole SMP-050 | ||||||

Depth (m) | 4m composites | 1m splits | Screen fire assays | |||

From | To | Au (g/t) 1 | Au (g/t) 2 | Ag (g/t) | Cu (ppm) | Au (g/t) 3 |

68 | 69 | 0.03 | 0.01 | <0.2 | 20 | - |

69 | 70 | 0.01 | <0.2 | 25 | - | |

70 | 71 | 0.05 | <0.2 | 53 | - | |

71 | 72 | 0.06 | <0.2 | 40 | - | |

72 | 73 | 11.95 | 0.55 | 0.3 | 46 | 0.55 |

73 | 74 | 1.36 | 1.0 | 26 | 2.10 | |

74 | 75 | 1.46 | 0.7 | 43 | 1.81 | |

75 | 76 | 44.30 | 6.7 | 62 | 45.60 | |

76 | 77 | 14.75 | 0.22 | <0.2 | 4 | 0.25 |

77 | 78 | 0.49 | <0.2 | 4 | 0.35 | |

78 | 79 | 4.83 | 0.7 | 10 | 7.51 | |

79 | 80 | 54.80 | 8.0 | 44 | 61.80 | |

80 | 81 | 2.54 | 12.55 | 2.0 | 23 | 9.02 |

81 | 82 | 0.21 | 0.2 | 28 | 0.24 | |

82 | 83 | 0.17 | <0.2 | 43 | - | |

83 | 84 | 0.04 | <0.2 | 11 | - | |

84 | 85 | 0.09 | 0.02 | <0.2 | 5 | - |

85 | 86 | 0.05 | <0.2 | 8 | - | |

86 | 87 | 0.02 | <0.2 | 45 | - | |

87 | 88 | 0.02 | <0.2 | 13 | - | |

Notes:

| ||||||

Table 2: Compiled assay results, SMP-050, 68-88m

Aton field crews then took sub-samples of the "L" samples, and combined them into 4m composite samples, thoroughly mixing and homogenising the samples. These 4m samples were then split down to c. 500-1,000g samples which were dispatched from site for gold fire assay analysis.

Upon receipt of the 4m composite assay results, selected 1m mineralised intervals were then selected with a further c. 500-1,000g sub-sample being split off from the retained material from the "L" bags and sent to the laboratory for gold, silver and copper analysis.

After the results of the 1m split samples were received, a further 165 samples were selected from the mineralised intervals, with another 1kg sub-sample being split off, this time from the "R" bags, and these were sent for metallic screen fire assay analysis.

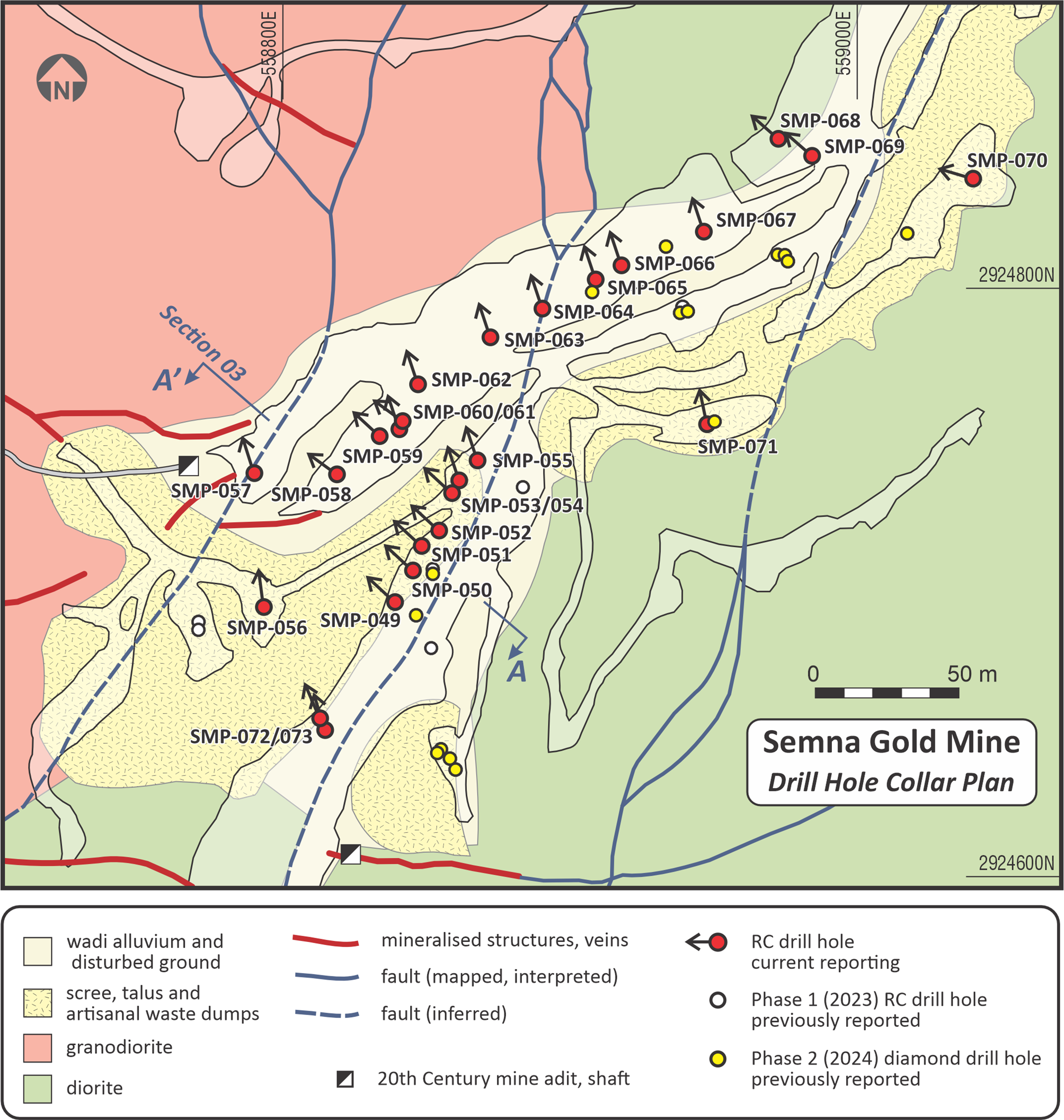

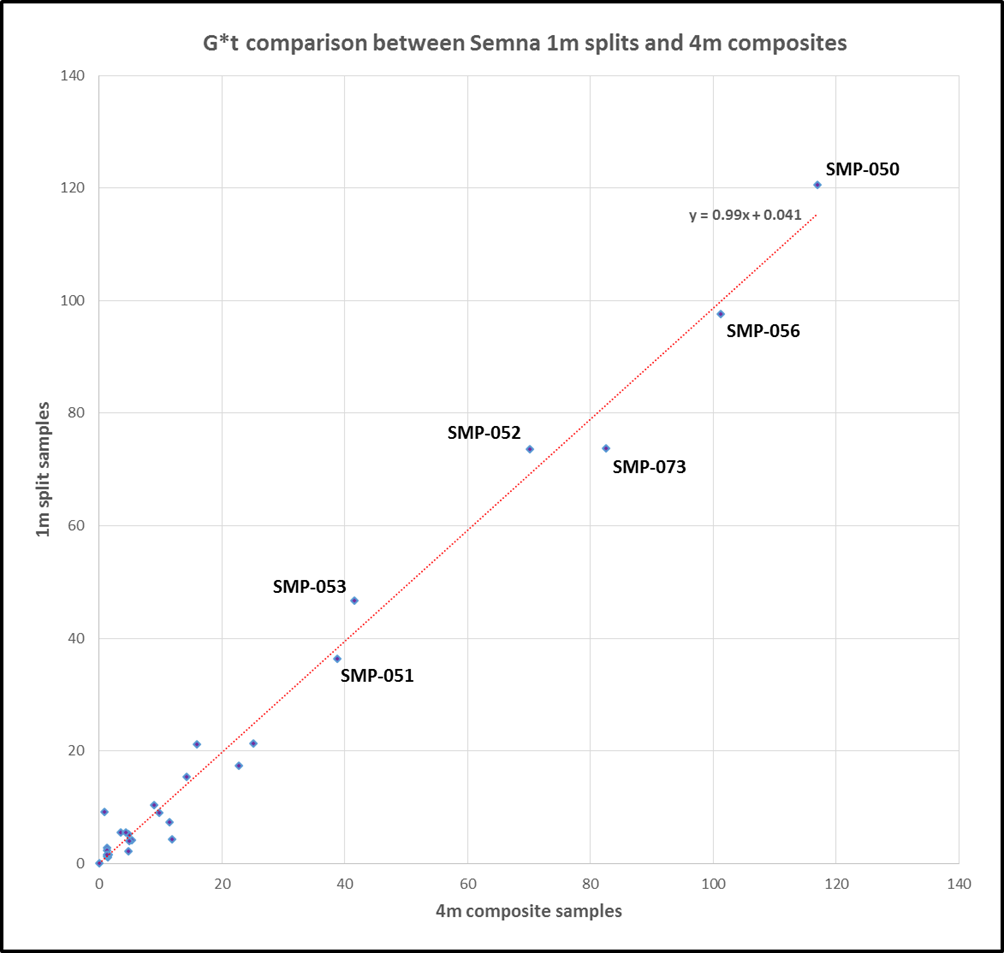

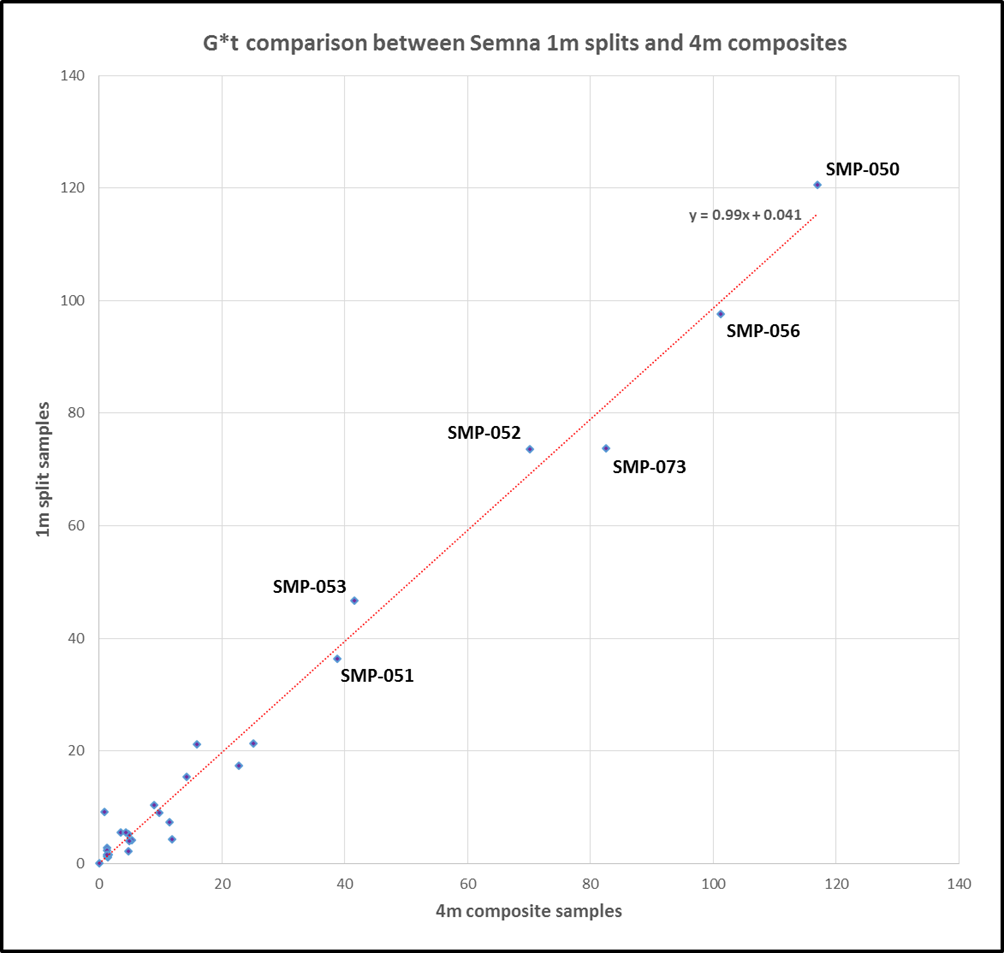

An example of all the assays received from the 3 different sampling techniques/assaying methods is presented in Table 2 above, showing the mineralised intersection from hole SMP-050 between 72-81m. Furthermore, a comparison was made between all the mineralised intervals from holes SMP-049 and SMP-073, using both the 4m composite sample assays and the 1m split sample assays, as a direct comparison cannot be made between individual 1m and 4m composite samples, and this is plotted as a scatter graph in Figure 7 below

Figure 7: Comparison between mineralised intervals from the 4m composite samples and the 1m split samples, holes SMP-049 to SMP-073

Figure 7 shows a generally very close correlation between the 1m split sample grades and the 4m composite sample grades, with the trendline showing a 99% correlation between the 2 sets of samples. This very close and accurate correlation indicates the validity of the sampling methodologies employed and the accuracy of the assays received from both the initial 4m composite samples and the subsequent 1m split samples.

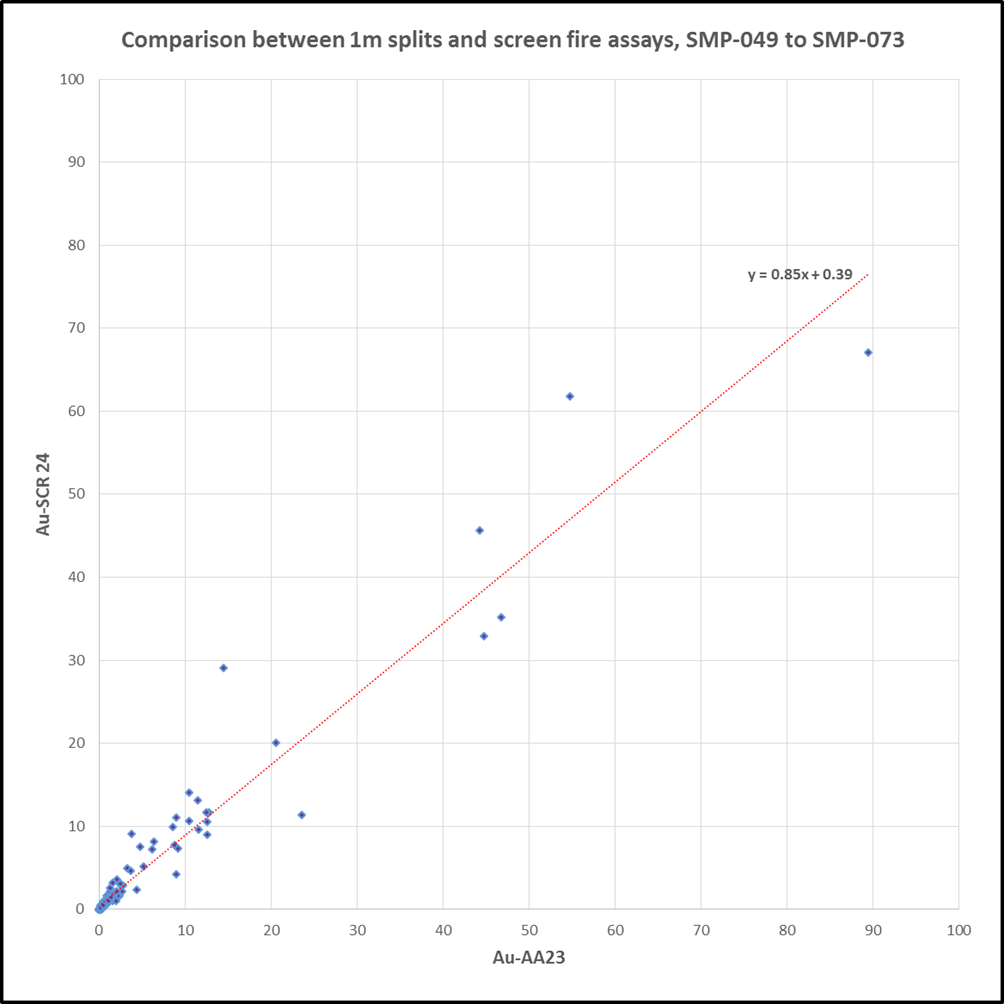

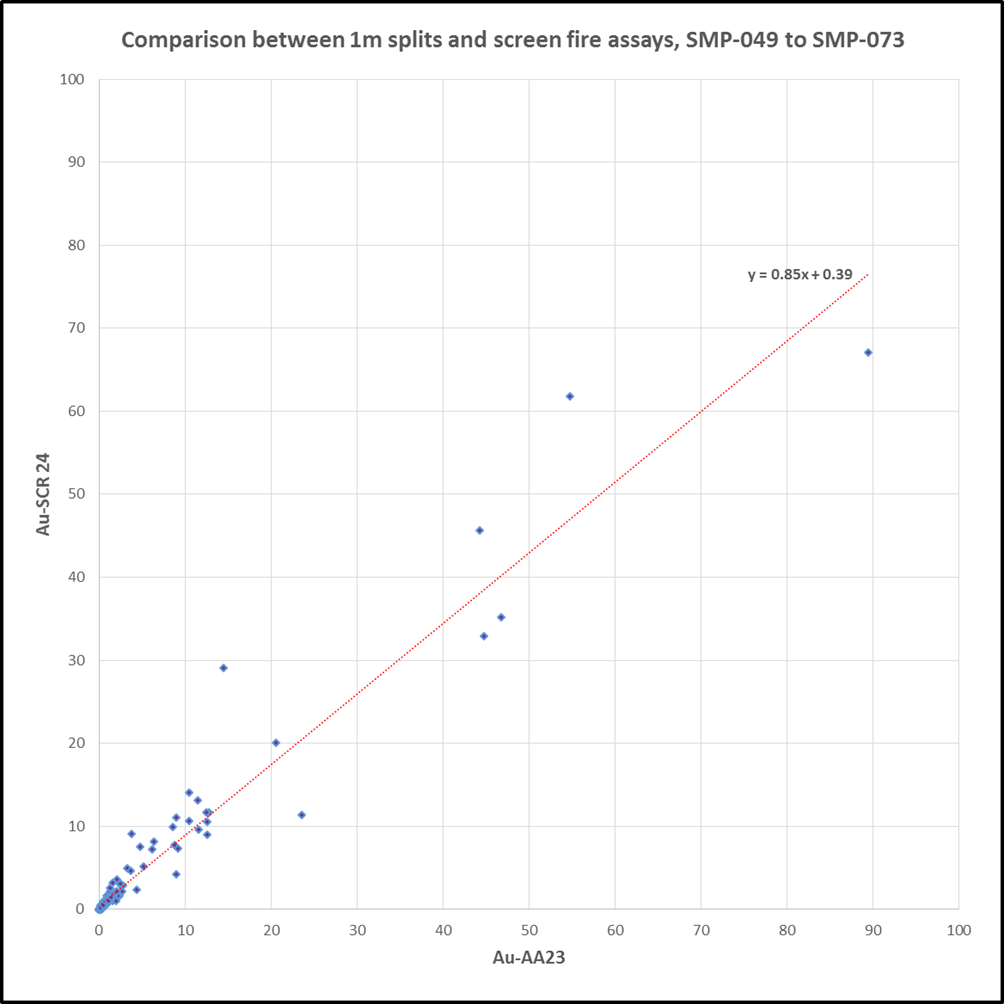

Figure 8: Comparison between conventional fire assay (Au-AA23) and metallic screen fire assay results (Au-SCR24), holes SMP-049 to SMP-073

A similar exercise was undertaken to assess the correlation between the conventional fire assay (Au-AA23) and the screen fire assay (Au-SCR24) results of the 165 1m samples that were submitted for screen fire assay analysis (Figure 8). The graph shows that the majority of samples analysed cluster at grades of below about 13-15 g/t Au, and that up to these grades the screen fire assay grades appear to be marginally higher than the original 1m conventional fire assay grades. However when the 8 higher grade assays are included the correlation becomes very dependent on the high grade outlier samples, with the overall correlation very heavily skewed by a single sample (SMP-056, 51-52m), which returned a 4m composite assay of 23.10 g/t Au between 48-52m, an Au-AA23 assay of 89.4 g/t Au from the subsequent 1m split, but a significantly lower Au-SCR24 assay of 67.1 g/t Au. Overall this analysis suggests that the screen fire assays appear to be lower than the original Au-AA23 analyses, which is a slightly surprising conclusion, but is explained by the nuggety distribution of coarse gold in the highest grade samples. In general, however, the correlation between the screen fire assay results and the original conventional fire assay results is quite close.

Sampling and analytical procedures

The RC drill holes were drilled at 5½" size (138-140mm diameter), using an Explorac 100 RC drilling rig. The rig was equipped with an onboard cone splitter which was set to produce 2 separate 1/8 split samples ("L" - laboratory and "R" - retain) which were collected into cloth bags directly from the splitter. The remaining c. 75% of the bulk percussion chip samples was collected directly from the cyclone into pre-written large plastic bags every metre, numbered with the hole number and hole depths. The bulk sample bags were laid out sequentially at the drill site. Between each metre of drilling the cyclone was cleaned out with compressed air, and the hole was blown clean to reduce the risk of downhole contamination. The bags were logged on the drill sites by Aton geologists. A representative sample of each metre was washed and stored in marked plastic chip trays, each containing 20m of samples, photographed, and retained onsite as a permanent record of the drill hole, with the bulk sample bags being retained at the drill sites.

The 1m "L" split samples, weighing approximately 4-5kg each were then transported to the Abu Marawat sample processing facility, where they were 1/2 riffle split into 2 separate sub-samples, weighing approximately 2-2.5kg. One of these sub-samples was marked and labelled, and retained at the laboratory for storage. The second 1m sub-samples were then combined into 4m composite samples, weighing approximately 8-10kg. These were thoroughly mixed and homogenised and again riffle split to produce nominal c. 500-1,000g 4m composite samples which were dispatched to ALS Minerals for analysis. Again the splitter was cleaned with compressed air between each sample. The 4m composite samples were allocated new sample numbers. The bulk reject material from the riffle split 4m composite samples was disposed of. QAQC samples were inserted into the 4m composite sample stream at a rate of approximately 1 certified reference material (or "standard" sample) every 60 samples, 1 blank sample every 30 samples, and 1 field duplicate split sample ("L" bag) or replicate sample (taken from the "R" bag) every 30 samples.

The "R" bags were retained separately onsite and stored at the Abu Marawat sample storage facility.

The dried and split 4m composite samples were shipped to ALS Minerals sample preparation laboratory at Marsa Alam, Egypt, where they were pulverised to a size fraction of better than 85% passing 75 microns. From this pulverised material a further sub-sample was split off with a nominal c. 100g size, which was shipped on to ALS Minerals at Rosia Montana, Romania for analysis. The reject pulp material was returned to the sample preparation facility at Rodruin, where it is also retained onsite

The 4m composite samples were analysed for gold by fire assay (30g charge) with an atomic absorption spectroscopy ("AAS") finish (analytical code Au-AA23). Any high grade gold samples (>10 g/t Au) were re-analysed using analytical code Au-GRA22 (also fire assay, with a 50g charge, and with a gravimetric finish).

Following receipt of the assay results of the 4m composite assay results, selected 1m mineralised intervals were then selected with a further c. 500-1,000g sub-sample being split off from the retained material from the "L" bags, and again allocated new sample numbers. QAQC samples were inserted into the 1m split sample stream at a rate of approximately 1 certified reference material/standard sample every 30 samples, 1 blank sample every 15 samples, and 1 field duplicate or replicate sample every 15 samples. The remaining material from the "L" bags was again retained onsite at Abu Marawat.

The 1m split samples were again sent to ALS Minerals Egypt for sample preparation and on to ALS Romania for gold, silver and copper analysis. Gold was again analysed using Au-AA25 and Au-GRA22 for overlimit assays. Samples were also analysed for silver and copper using an aqua regia digest followed by an AAS finish (analytical codes Ag-AA45 and Cu-AA45).

Following receipt of the assay results of the 1m composite assay results, a further 165 samples were then selected from the mineralised intervals, with a further c. 1,000g sub-sample being split off from the retained "R" bags, and these samples were again allocated new sample numbers. The residual material from the "R" bags was re-bagged, and was again retained onsite at Abu Marawat.

This second tranche of 1m split samples were again sent to ALS Minerals Egypt who arranged for transport directly on to ALS Romania for metallic screen fire assay analysis for gold (analytical code Au-SCR24). No QAQC samples were inserted into this sample stream.

About Aton Resources Inc.

Aton Resources Inc. (AAN: TSX-V) is focused on its 100% owned Abu Marawat Concession ("Abu Marawat"), located in Egypt's Arabian-Nubian Shield, approximately 200 km north of Centamin's world-class Sukari gold mine. Aton has identified numerous gold and base metal exploration targets at Abu Marawat, including the Hamama deposit in the west, the Abu Marawat deposit in the northeast, and the Rodruin deposit in the south of the Concession. Two historic British gold mines are also located on the Concession at Semna and Sir Bakis. Aton has identified several distinct geological trends within Abu Marawat, which display potential for the development of a variety of styles of precious and base metal mineralisation. The Abu Marawat exploitation lease is 57.66 km2 in size, covering the Hamama West and Rodruin mineral deposits, and was established In January 2024 and is valid for an initial period of 20 years. The Concession also includes an additional 255.0 km2 of exploration areas at Abu Marawat, retained for a further period of 4 years from January 2024. Abu Marawat is located in an area of excellent infrastructure; a four-lane highway, a 220kV power line, and a water pipeline are in close proximity, as are the international airports at Hurghada and Luxor.

Qualified person

The technical information contained in this News Release was prepared by Javier Orduña BSc (hons), MSc, MCSM, DIC, MAIG, SEG(M), Chief Geologist of Aton Resources Inc. Mr. Orduña is a qualified person (QP) under National Instrument 43-101 Standards of Disclosure for Mineral Projects.

For further information regarding Aton Resources Inc., please visit us at www.atonresources.com or contact:

TONNO VAHK

Chief Executive Officer

Tel: +1 604 318 0390

Email: info@atonresources.com

Note Regarding Forward-Looking Statements

Some of the statements contained in this release are forward-looking statements. Since forward-looking statements address future events and conditions; by their very nature they involve inherent risks and uncertainties. Actual results in each case could differ materially from those currently anticipated in such statements.

Neither TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Appendix A - Semna phase 3 RC drill hole collar details, SMP-049 to SMP-073

Hole ID | Collar co-ordinates 1,2 | EOH depth (m) | Dip | Grid azimuth | Comments | ||

X | Y | Z | |||||

SMP-049 | 558839.6 | 2924693.3 | 569.9 | 90 | -54.6 | 307.8 | |

SMP-050 | 558846.0 | 2924703.6 | 569.2 | 130 | -52.7 | 307.7 | |

SMP-051 | 558848.8 | 2924711.9 | 568.8 | 120 | -48.5 | 313.7 | |

SMP-052 | 558855.4 | 2924717.0 | 568.8 | 120 | -49.3 | 312.1 | |

SMP-053 | 558859.7 | 2924730.0 | 568.3 | 110 | -48.1 | 311.7 | |

SMP-054 | 558861.9 | 2924734.2 | 568.1 | 110 | -54.3 | 340.8 | |

SMP-055 | 558868.8 | 2924741.2 | 568.1 | 100 | -54.2 | 339.5 | |

SMP-056 | 558794.0 | 2924691.3 | 589.1 | 110 | -54.8 | 349.6 | |

SMP-057 | 558790.5 | 2924736.5 | 565.9 | 50 | -53.2 | 340.1 | |

SMP-058 | 558819.6 | 2924736.0 | 559.0 | 70 | -49.9 | 308.5 | |

SMP-059 | 558834.4 | 2924749.4 | 559.2 | 60 | -49.0 | 310.1 | |

SMP-060 | 558842.5 | 2924754.3 | 559.8 | 95 | -49.9 | 311.7 | |

SMP-061 | 558841.4 | 2924751.5 | 559.7 | 90 | -59.5 | 339.7 | |

SMP-062 | 558847.6 | 2924767.2 | 560.7 | 60 | -50.3 | 340.1 | |

SMP-063 | 558873.0 | 2924782.7 | 561.8 | 60 | -49.0 | 340.5 | |

SMP-064 | 558891.2 | 2924792.6 | 561.6 | 60 | -60.0 | 339.7 | |

SMP-065 | 558909.8 | 2924802.8 | 560.2 | 60 | -43.9 | 340.0 | |

SMP-066 | 558918.7 | 2924807.4 | 559.5 | 60 | -59.8 | 341.0 | |

SMP-067 | 558947.4 | 2924818.9 | 559.3 | 55 | -48.8 | 338.8 | |

SMP-068 | 558973.4 | 2924850.5 | 563.8 | 50 | -45.6 | 309.5 | |

SMP-069 | 558985.6 | 2924844.4 | 563.8 | 100 | -53.9 | 309.4 | |

SMP-070 | 559041.0 | 2924837.0 | 575.5 | 25 | -56.8 | 284.5 | Hole abandoned, not assayed |

SMP-071 | 558948.7 | 2924753.4 | 577.2 | 184 | -51.7 | 342.7 | Twin of diamond hole SMD-027 |

SMP-072 | 558813.9 | 2924653.0 | 570.6 | 120 | -42.6 | 339.1 | |

SMP-073 | 558815.3 | 2924649.2 | 570.5 | 185 | -58.6 | 335.9 | |

Notes:

| |||||||

Appendix B - Semna phase 3 RC drill hole screen fire assay intersections (1m splits)

Hole ID | Intersection (m) | Au (g/t) | Ag (g/t) | Cu (%) | Comments | ||

From | To | Interval | |||||

SMP-049 | 81 | 89 | 8 | 0.65 | 8.4 | 0.41 | |

SMP-050 | 55 | 59 | 4 | 0.69 | 0.3 | 0.00 | |

and | 72 | 81 | 9 | 14.33 | 2.2 | 0.00 | Offset Vein? |

incl. | 75 | 76 | 1 | 45.60 | 6.7 | 0.01 | |

and incl. | 78 | 81 | 3 | 26.11 | 3.6 | 0.00 | |

SMP-051 | 35 | 49 | 14 | 2.93 | 0.7 | 0.01 | |

incl. | 44 | 49 | 5 | 7.65 | 1.7 | 0.01 | |

SMP-052 | 44 | 51 | 7 | 8.66 | 1.4 | 0.00 | Offset Vein? |

incl. | 44 | 46 | 2 | 8.30 | 0.9 | 0.00 | |

and incl. | 49 | 51 | 2 | 21.73 | 3.9 | 0.00 | |

SMP-053 | 27 | 29 | 2 | 1.03 | 1.6 | 0.09 | |

and | 38 | 44 | 6 | 6.16 | 0.8 | 0.00 | Offset Vein? |

SMP-054 | 36 | 37 | 1 | 1.40 | 0.3 | 0.01 | |

and | 98 | 99 | 1 | 2.11 | 0.4 | 0.00 | |

SMP-055 | - | - | - | - | - | - | No samples sent for screen fire assay |

SMP-056 | 39 | 53 | 14 | 5.41 | 1.1 | 0.04 | |

incl. | 39 | 44 | 5 | 2.53 | 0.2 | 0.01 | |

and incl. | 50 | 53 | 3 | 22.57 | 4.3 | 0.00 | |

SMP-057 | 2 | 13 | 11 | 0.45 | 0.2 | 0.17 | Includes 3m NSR (old/recent mine workings) |

SMP-058 | 1 | 10 | 9 | 1.85 | 0.3 | 0.03 | |

SMP-059 | 2 | 5 | 3 | 0.78 | 0.4 | 0.03 | |

SMP-060 | 8 | 12 | 4 | 1.16 | 1.9 | 0.06 | |

SMP-061 | 6 | 13 | 7 | 1.26 | 0.5 | 0.01 | |

incl. | 11 | 13 | 2 | 3.62 | 1.3 | 0.02 | |

SMP-062 | 18 | 20 | 2 | 3.77 | 0.5 | 0.01 | |

SMP-063 | - | - | - | - | - | - | No samples sent for screen fire assay |

SMP-064 | - | - | - | - | - | - | NSA (28-30m: 2m @ 0.67 g/t Au) |

SMP-065 | 6 | 15 | 9 | 1.07 | 0.2 | 0.00 | |

and | 30 | 31 | 1 | 2.59 | 0.2 | 0.01 | |

SMP-066 | 30 | 40 | 10 | 1.99 | 2.9 | 0.02 | |

incl. | 30 | 32 | 2 | 4.43 | 13.2 | 0.06 | |

and incl. | 37 | 40 | 3 | 3.65 | 0.5 | 0.01 | |

SMP-067 | 29 | 31 | 2 | 5.09 | 0.6 | 0.02 | |

and | 49 | 53 | 4 | 1.06 | 0.1 | 0.00 | |

SMP-068 | 40 | 42 | 2 | 2.80 | 0.8 | 0.00 | |

SMP-069 | 77 | 81 | 4 | 3.98 | 3.3 | 0.21 | |

SMP-071 | 49 | 50 | 1 | 1.57 | 0.2 | 0.01 | Twin of DD hole SMD-027 |

and | 125 | 128 | 3 | 10.06 | 0.8 | 0.00 | Twin of SMD-027 (135.8-139.0m: 3.1m @ 8.10 g/t Au) |

and | 164 | 167 | 3 | 2.04 | 2.2 | 0.05 | Twin of SMD-027 (162.2-166.3m: 4.1m @ 1.03 g/t Au) |

SMP-072 | 68 | 74 | 6 | 0.61 | 0.7 | 0.01 | |

Hole ID | Intersection (m) | Au (g/t) | Ag (g/t) | Cu (%) | Comments | ||

From | To | Interval | |||||

SMP-073 | 97 | 100 | 3 | 0.61 | 0.3 | 0.02 | |

and | 138 | 144 | 6 | 10.74 | 0.0 | 0.00 | Possible depth extension of Main Vein / |

and | 177 | 179 | 2 | 0.77 | 0.3 | 0.01 | Offset Vein? |

Notes:

| |||||||

Appendix C - Semna phase 3 RC drill hole conventional fire assay intersections (1m splits)

Hole ID | Intersection (m) | Au (g/t) | Ag (g/t) | Cu (%) | Comments | ||

From | To | Interval | |||||

SMP-049 | 81 | 89 | 8 | 0.68 | 8.4 | 0.41 | |

incl. | 86 | 89 | 3 | 1.15 | 18.3 | 0.49 | |

SMP-050 | 55 | 59 | 4 | 0.69 | 0.3 | 0.00 | |

and | 72 | 81 | 9 | 13.39 | 2.2 | 0.00 | Offset Vein? |

incl. | 75 | 76 | 1 | 44.30 | 6.7 | 0.01 | |

and incl. | 78 | 81 | 3 | 24.06 | 3.6 | 0.00 | |

SMP-051 | 35 | 49 | 14 | 2.60 | 0.7 | 0.01 | Offset Vein? |

incl. | 47 | 49 | 2 | 15.55 | 4.0 | 0.00 | |

SMP-052 | 44 | 51 | 7 | 10.52 | 1.4 | 0.00 | Offset Vein? |

incl. | 44 | 46 | 2 | 8.02 | 0.9 | 0.00 | |

and incl. | 49 | 51 | 2 | 28.70 | 3.9 | 0.00 | |

SMP-053 | 27 | 29 | 2 | 1.43 | 1.6 | 0.09 | |

and | 38 | 44 | 6 | 7.79 | 0.8 | 0.00 | Offset Vein? |

SMP-054 | 36 | 37 | 1 | 1.12 | 0.3 | 0.01 | |

and | 98 | 99 | 1 | 1.26 | 0.4 | 0.00 | |

SMP-055 | - | - | - | - | - | - | No 1m split samples sent for re-assay |

SMP-056 | 39 | 53 | 14 | 6.97 | 1.1 | 0.00 | |

incl. | 39 | 44 | 5 | 1.43 | 0.2 | 0.01 | |

and incl. | 51 | 53 | 2 | 44.90 | 6.4 | 0.00 | |

SMP-057 | 2 | 13 | 11 | 0.47 | 0.2 | 0.17 | Includes 3m NSR (old/recent mine workings) |

SMP-058 | 1 | 10 | 9 | 1.92 | 0.3 | 0.03 | |

SMP-059 | 2 | 5 | 3 | 0.75 | 0.4 | 0.03 | |

SMP-060 | 8 | 12 | 4 | 1.04 | 1.9 | 0.06 | |

SMP-061 | 11 | 13 | 2 | 3.63 | 1.3 | 0.02 | |

SMP-062 | 19 | 20 | 1 | 9.21 | 0.9 | 0.01 | |

SMP-063 | - | - | - | - | - | - | NSA > 0.17 g/t Au |

SMP-064 | - | - | - | - | - | - | NSA (28-30m: 2m @ 0.62 g/t Au) |

SMP-065 | 7 | 15 | 8 | 1.19 | 0.2 | 0.00 | |

SMP-066 | 30 | 40 | 10 | 2.11 | 2.9 | 0.02 | |

incl. | 30 | 32 | 2 | 3.62 | 13.2 | 0.06 | |

and incl. | 37 | 40 | 3 | 4.60 | 0.5 | 0.01 | |

SMP-067 | 28 | 31 | 3 | 3.00 | 0.4 | 0.01 | |

and | 44 | 53 | 9 | 0.62 | 0.1 | 0.00 | |

incl. | 49 | 53 | 4 | 1.05 | 0.1 | 0.00 | |

SMP-068 | 40 | 42 | 2 | 2.17 | 0.8 | 0.00 | |

SMP-069 | 77 | 81 | 4 | 5.33 | 3.3 | 0.21 | |

SMP-071 | 49 | 50 | 1 | 1.73 | 0.2 | 0.01 | Twin of DD hole SMD-027 |

and | 125 | 128 | 3 | 5.14 | 0.8 | 0.00 | Twin of SMD-027 (135.8-139.0m: 3.1m @ 8.10 g/t Au) |

and | 164 | 167 | 3 | 1.31 | 2.2 | 0.05 | Twin of SMD-027 (162.2-166.3m: 4.1m @ 1.03 g/t Au) |

Hole ID | Intersection (m) | Au (g/t) | Ag (g/t) | Cu (%) | Comments | ||

From | To | Interval | |||||

SMP-072 | 68 | 74 | 6 | 0.37 | 0.7 | 0.01 | |

SMP-073 | 97 | 99 | 2 | 0.74 | 0.4 | 0.03 | |

and | 138 | 144 | 6 | 12.29 | 1.9 | 0.00 | Possible depth extension of Main Vein / |

and | 177 | 179 | 2 | 0.79 | 0.3 | 0.01 | Offset Vein? |

Notes: 1) Mineralised intervals were calculated using a nominal cut-off of 0.5 g/t Au 2) NSR: no sample recovery; NSA: no significant assays | |||||||

Appendix D - Semna phase 3 RC drill hole conventional fire assay intersections (4m composites)

Hole ID | Intersection (m) | Au (g/t) | Comments | ||

From | To | Interval | |||

SMP-049 | 80 | 88 | 8 | 0.44 | |

SMP-050 | 72 | 84 | 12 | 9.75 | Offset Vein? |

SMP-051 | 40 | 52 | 12 | 3.23 | Offset Vein? |

SMP-052 | 44 | 52 | 8 | 8.76 | Offset Vein? |

SMP-053 | 36 | 44 | 8 | 5.19 | Offset Vein? |

SMP-054 | 36 | 40 | 4 | 0.36 | |

and | 96 | 100 | 4 | 0.32 | |

SMP-055 | - | - | - | - | NSA > 0.03 g/t Au |

SMP-056 | 36 | 52 | 16 | 6.32 | |

SMP-057 | 2 | 12 | 10 | 0.47 | Includes 3m NSR (old/recent mine workings) |

SMP-058 | 0 | 12 | 12 | 1.89 | |

SMP-059 | 1 | 8 | 7 | 0.69 | |

SMP-060 | 8 | 12 | 4 | 1.34 | |

SMP-061 | 8 | 16 | 8 | 1.44 | |

SMP-062 | - | - | - | - | NSA > 0.21 g/t Au (16-20m) |

SMP-063 | - | - | - | - | NSA > 0.10 g/t Au (8-16m) |

SMP-064 | - | - | - | - | NSA > 0.35 g/t Au (28-32m) |

SMP-065 | 8 | 16 | 8 | 1.12 | |

SMP-066 | 28 | 40 | 12 | 1.32 | |

SMP-067 | 28 | 32 | 4 | 2.46 | |

and | 48 | 55 | 7 | 0.62 | |

SMP-068 | 40 | 44 | 4 | 2.98 | |

SMP-069 | 76 | 84 | 8 | 3.14 | |

SMP-070 | - | - | - | - | Hole abandoned early, not assayed |

SMP-071 | 124 | 128 | 4 | 3.56 | Twin of SMD-027 (135.83-143.80m: 3.13m @ |

and | 148 | 152 | 4 | 0.61 | 8.10 g/t Au) |

and | 164 | 168 | 4 | 1.25 | SMD-027: 162.20-166.29m: 4.09m @ 1.03 g/t Au) |

SMP-072 | 68 | 72 | 4 | 0.33 | |

SMP-073 | 96 | 100 | 4 | 0.41 | |

and | 136 | 144 | 8 | 10.32 | Possible depth extension of Main Vein / Offset Vein? |

and | 176 | 180 | 4 | 0.33 | |

Notes: 1) Mineralised intervals were calculated using subjectively, but with a nominal cut-off of 0.5 g/t Au 2) NSR: no sample recovery; NSA: no significant assays | |||||

SOURCE: Aton Resources, Inc.

Related Images

View the original press release on ACCESS Newswire