Highlights from 2023-24 Drill Program* include:

From Bo_RC_12:

- 5.79% WO₃ over 2.0 metres (182-184m)

- 1.12% WO₃ over 4.0 metres (246-250m, within 12m from 82m to 94m of 0.40%)

- 0.78% WO₃ over 12.0 metres (82-94m, within 20m from 82m to 102m of 0.50%)

- 0.50% WO₃ over 20.0 metres (82-102m)

From Bo_RC_11:

- 1.75% WO₃ over 10.0 metres (140-150m, within 38m from 112m to 150m of 0.56%)

- 0.56% WO₃ over 38.0 metres (112-150m)

From Bo_RC_13:

- 0.68% WO₃ over 2.0 metres (208-210m)

From Bo_RC_02:

- 0.63% WO₃ over 16.0 metres (62-78m, within 108m from 26m to 134m of 0.22%)

From Bo_Met_01:

- 0.60% WO₃ over 5.0 metres (60-65m, within 106m from 60m to 166m of 0.21%)

- 0.21% WO3 over 106.0 metres (60-166m)

From Bo_Met_02a:

- 0.53% WO₃ over 23.0 metres (62-85m)

*As previously reported in the Borralha Technical Report (see below).

Vancouver, British Columbia--(Newsfile Corp. - September 23, 2025) - Allied Critical Metals Inc. (CSE: ACM) (OTCQB: ACMIF) (FSE: 0VJ0) ("Allied" or the "Company"), which is focused on its 100% owned past producing Borralha and Vila Verde tungsten projects in northern Portugal, is pleased to announce highlights from its 2023 & 2024 drill program on its 100% owned Borralha Tungsten Project. Although the drill results were included in its current technical report on the Borralha Tungsten Project (the "Borralha Technical Report"), the individual drill results were never individually showcased. The Borralha Technical Report is entitled, "Technical Report on the Borralha Property, Parish of Salto, District of Vila Real, Portugal', dated effective July 31, 2024" which is available under the Company's profile on SEDAR+ at www.sedarplus.ca.

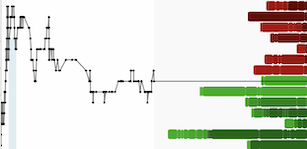

During Allied's 2023-2024 Borralha drill program, more than 3,685 meters were drilled in 16 drill holes in the Santa Helena Breccia, as described in the Borralha Technical Report, which includes the following notable intercept highlights in the table below.

Table 1: Highlights of Intercepts from 2023-24 Borralha Drill Program

| Drill Hole ID | From (m) | To (m) | DH length (m) | True Width factor | True Width* (m) | WO3 (%) | Cu (ppm) | Ag (ppm) |

| Bo_Met_01 | 60.0 | 166.0 | 106.0 | 0.76 | 80.4 | 0.21 | 863 | 5.2 |

| incl. | 60.0 | 65.0 | 5.0 | 0.76 | 3.8 | 0.60 | 247 | 1.8 |

| Bo_Met_02a | 62.0 | 85.0 | 23.0 | 0.95 | 21.9 | 0.53 | 1215 | 5.8 |

| Bo_RC_02 | 26.0 | 134.0 | 108.0 | 0.91 | 98.3 | 0.22 | 1170 | 4.9 |

| incl. | 62.0 | 78.0 | 16.0 | 0.91 | 14.6 | 0.63 | 1533 | 4.9 |

| Bo_RC_11 | 112.0 | 150.0 | 38.0 | 0.78 | 29.5 | 0.56 | 295 | 1.9 |

| incl. | 140.0 | 150.0 | 10.0 | 0.78 | 7.8 | 1.75 | 204 | 1.5 |

| + | 256.0 | 268.0 | 12.0 | tbd | - | 0.20 | 436 | 3.8 |

| Bo_RC_12 | 82.0 | 102.0 | 20.0 | 0.96 | 19.3 | 0.50 | 2087 | 10.2 |

| incl. | 82.0 | 94.0 | 12.0 | 0.96 | 11.6 | 0.78 | 2038 | 9.5 |

| + | 182.0 | 184.0 | 2.0 | 0.92 | 1.8 | 5.79 | 334 | 3.8 |

| + | 238.0 | 250.0 | 12.0 | 0.90 | 10.8 | 0.40 | 600 | 2.3 |

| incl. | 246.0 | 250.0 | 4.0 | 0.90 | 3.6 | 1.12 | 1260 | 4.6 |

| Bo_RC_13 | 208.0 | 210.0 | 2.0 | 0.90 | 1.8 | 0.68 | 217 | 1.9 |

*Reported intervals are downhole lengths. Estimated true widths were calculated from hole orientation and the interpreted geometry of the mineralized corridors. Estimates may vary locally where geometry changes. Where intervals fall outside the resource block-model domains, the true width is not known and only the downhole length is reported.

Table 2: Drill Hole Collar Locations

| Drill Hole ID | Coordinates (WGS84) | Az.(º) | Dip.(º) | DEPTH (m) | |

| Bo_Met_01 | 585521 | 4611357 | 180 | 80 | 253.20 |

| Bo_Met_02 | 585458 | 4611315 | 110 | 53 | 72.90 |

| Bo_Met_02a | 585459 | 4611316 | 118 | 50 | 164.30 |

| Bo_RC_01 | 585521 | 4611355 | 180 | 80 | 219.00 |

| Bo_RC_02 | 585469 | 4611279 | 130 | 60 | 150.00 |

| Bo_RC_03 | 585467 | 4611472 | 109 | 60 | 237.00 |

| Bo_RC_04 | 585588 | 4611506 | 230 | 70 | 264.00 |

| Bo_RC_05 | 585588 | 4611444 | 230 | 70 | 306.00 |

| Bo_RC_06 | 585587 | 4611380 | 240 | 70 | 236.00 |

| Bo_RC_09 | 585455 | 4611387 | 106 | 60 | 250.00 |

| Bo_RC_08 | 585417 | 4611353 | 105 | 60 | 236.00 |

| Bo_RC_07 | 585423 | 4611294 | 100 | 55 | 195.00 |

| Bo_RC_11 | 585539 | 4611503 | - | 90 | 376.00 |

| Bo_RC_10 | 585461 | 4611195 | 90 | 60 | 150.00 |

| Bo_RC_12 | 585383 | 4611329 | 100 | 60 | 300.00 |

| Bo_RC_13 | 585406 | 4611377 | 105 | 65 | 276.00 |

| actual sum | |||||

| Total | 3685.4 | ||||

The Company has continued its exploration of the Santa Helena Breccia with its 2025 drill program which is also focused on the Santa Helena Breccia (SHB) of Borralha.

"The company invested approximately $4.1 million in 2023 & 2024 on exploration to further give confidence to investors prior to its public listing," Roy Bonnell, CEO & Director, Allied Critical Metals, stated. "We are now working to provide an updated version of the Mineral Resource Report for Borralha in Q4 2025, which is expected to include more than approximately 5,700 metres of drill results from this year's program."

Allied's flagship Borralha Tungsten Project, strategically located in northern Portugal, represents one of the most significant undeveloped tungsten deposits in the western world having a potential near-term source of supply outside of the domain of China and Russia. With the NI 43-101 mineral resource estimate of 4.98 Mt @ 0.22% WO₃ (Indicated) and 7.01 Mt @ 0.20% WO₃ (Inferred) previously reported in the Borralha Technical Report, Borralha has the potential to provide a stable and scalable source of tungsten concentrate to Western markets. On September 4, 2025, Allied announced a drill intercept of 12.0 metres @ 4.27% WO3 including 6.0 metres @ 8.39% WO3 from 252.00 metres downhole, confirming one of the highest-grade tungsten intercepts reported in Western exploration, especially for high quality wolframite tungsten mineralization.

Technical Information and Quality Assurance/Quality Control (QA/QC)

During the 2023-24 drilling campaign three PQ-size diamond drill holes and thirteen reverse circulation boreholes, totalling 3,685.40 metres of drilling, were completed to their proposed lengths. Minerália was contracted to supervise and manage the drilling program that included three PQ-size diamond drill holes, namely Bo_Met_01, _02 and _ 02a, totalling 490.4 metres of drilling and thirteen reverse circulation drill holes, namely Bo_RC_01 to _13 that totalled 3,195.0 metres of drilling. Diamond drill hole Bo_Met_02 intersected old underground workings and was abandoned and re-drilled nearby as Bo_Met_02a. As of the effective date of this report, the Company has drill tested the SHB with 5,602.95 metres of drilling, infilling historical drill holes and extending exploration towards the southern part of the SHB.

The cores from the two diamond holes, Bo_Met_01 and _ 02a were halved length wise after logging and one-half of the cores were shipped to Wardell Armstrong International Ltd. with offices in Truro, London for metallurgical test work. The other half of drill core was sampled and shipped to the ALS preparatory laboratories in Seville, Spain and later to the ALS certified assay laboratories in Dublin Road, Loughrea, Co., Ireland for multi-element ICP analyses. The later 1-metre reverse circulation drill cuttings were composited into 2-metre samples and direct shipped to the ALS preparatory laboratories in Seville, Spain and later to the ALS certified assay laboratories in Dublin Road, Loughrea, Co., Ireland.

The analytical samples were collected directly from the rig splitter according to a sampling list that documented the metres and sampling sequence for each drill hole. This list also identified which sample should be collected in duplicate as well as which certified reference material ('CRM') were to be placed in the numerical sequence. The CRMs were randomly inserted at every 20 samples (5%), and duplicate samples were collected every 20 samples (5%). Thus, there's an alternating CRM and Duplicate every 10th sample.

The analytical and reject samples are then transported in boxes from the drilling site to the core shed by a designated employee. The analytical samples were stored on labelled palettes for later direct shipping to the ALS preparation laboratories in Seville, Spain. Later, the pulp and reject samples were securely stored in the logging room on the property.

RC samples were prepared by ALS preparation laboratory in Seville, Spain, crushing the sample with up to 70% of the material passing a 2 mm screen, and then each sample was split to 250 g and pulverized with hardened steel to 85% passing a 75 μm screen. Each resultant sub-sample was then direct shipped to their certified assay laboratory Dublin Road, Loughrea, Co., Ireland.

The samples are analyzed by the ME-MS81 ALS method that applies a lithium borate fusion to the sample and the result of this fusion is measured by applying an ICP-MS. It is also applied to the ALS ME-4ACD81 procedure which reports base metals by a 4-acid digestion and later analyzed by an ICP-MS procedure. Any over-limit tungsten values were re-analysed at the same laboratory by a W-XRF15b procedure that uses a lithium borate fusion with an XRF analysis. The analytical results were then securely emailed to the company.

To the best of the Company's knowledge, no drilling, sampling, recovery, or other factors have been identified that would materially affect the accuracy or reliability of the data referenced herein. As indicated further above, these drilling results and related procedures and technical information were also detailed by an independent qualified person in the Borralha Technical Report which is available under the Company's profile on SEDAR+ at www.sedarplus.ca.

Qualified Person

The scientific and technical information in this news release has been reviewed and approved by Mr. Vítor Arezes, BSc, MIMMM (QMR) (Membership Nº. 703197, Vice-President Exploration of Allied Critical Metals, who is a Qualified Person for the purposes of National Instrument 43-101 - Standards of Disclosure for Mineral Projects. Mr. Arezes is not independent of Allied Critical Metals Inc. as he is an officer of the Company.

Understanding Tungsten

To understand tungsten, it is critical to understand the difference between wolframite tungsten mineralization and scheelite tungsten mineralization. Scheelite often reports higher grades (0.3%-1.0% WO₃) but is more costly and complex to process, requiring flotation methods with higher capital and operating expenditures and lower recoveries.i In contrast, wolframite, which is the focus of Allied, can be processed more efficiently using gravity and magnetic separation, resulting in lower costs and higher recoveries, making lower grades (~0.15%-0.25% WO₃) economically viable in wolframite deposits. For example, a wolframite deposit with 0.4% WO₃ over 3 metres can be more profitable than a scheelite deposit with 0.7% WO₃ over the same interval due to lower processing costs and higher recovery rates.ii

In Western exploration drilling, tungsten grades typically range from 0.3% to 1.0% WO₃.iii The cut-off grade for economic viability is generally around 0.1% WO₃, with highly efficient operations able to mine at grades as low as 0.08% WO₃. Skarn deposits, a common deposit type, typically range from 0.34% to 1.4% WO₃, with intercepts of 0.4% WO₃ over 1-5 metres considered very good and 0.7% WO₃ over 1-3 metres considered very high-grade.iv Intercept lengths can range from 0.6 metres to over 100 metres, with longer intercepts at strong grades generally preferred for economic mining. A result like 0.5% WO₃ over 3 metres is generally considered strong within Western tungsten exploration benchmarks, especially for wolframite tungsten mineralization.v

It is also important to recognize that China, Russia, and North Korea control approximately 87% of the world's tungsten supply, using cheap labor and minimal environmental standards in authoritarian regimes. vi As a result, production costs and grades in these countries are not comparable to Western projects, which operate under higher labor, ESG, and energy cost structures. Evaluating projects outside these regions provides a realistic benchmark for what grades and intercepts are economically viable while supporting secure, NATO-aligned supply chains.

For Allied, this context is significant. Wolframite tungsten grades, ranging from 0.2% to 1.0% WO₃ are strong global wolframite benchmark values. The Company's focus on wolframite ensures lower processing costs and higher recoveries, supporting project economics even at lower grades. Allied's operations in secure jurisdictions align with Western critical mineral needs, avoiding geopolitical risks associated with China and Russia while positioning the Company to benefit from growing tungsten demand across defense, aerospace, and electrification sectors. Allied's strong grades, low-cost processing advantages, and secure location position it as a strategic and responsible tungsten exploration company, well placed to support robust project economics in a rising-demand market. vii

About Allied Critical Metals Inc.

Allied Critical Metals Inc. (CSE: ACM) (OTCQB: ACMIF) (FSE: 0VJ0) is a Canadian-based mining company focused on the expansion and revitalization of its 100% owned past producing Borralha Tungsten Project and the Vila Verde Tungsten Project in northern Portugal with advantageous wolframite tungsten mineralization. Tungsten has been designated a critical metal by the United States and other western countries, as they are aggressively seeking friendly sources of this unique metal. Currently, China, Russia and North Korea represent approximately 86% of the total global supply and reserves. Tungsten is used in a variety of industries such as defense, automotive, manufacturing, electronics, and energy.

ON BEHALF OF THE BOARD OF DIRECTORS

"Roy Bonnell"

Roy Bonnell

CEO and Director

For further information or investor relations inquiries, please contact:

Dave Burwell

Vice President, Corporate Development

Email: daveb@alliedcritical.com

Tel: 403-410-7907

Toll Free: 1-888-221-0915

Please visit our website at www.alliedcritical.com.

Also visit us at:

LinkedIn: https://www.linkedin.com/company/allied-critical-metals-inc

X: https://x.com/@alliedcritical/

Instagram: https://www.instagram.com/alliedcriticalmetals/

The Canadian Stock Exchange does not accept responsibility for the adequacy or accuracy of this release.

Cautionary Statement Regarding Forward-Looking Information

This news release contains "forward-looking statements", including with respect to the use of proceeds. Wherever possible, words such as "may", "would", "could", "should", "will", "anticipate", "believe", "plan", "expect", "intend", "estimate", "potential for" and similar expressions have been used to identify these forward-looking statements. These forward-looking statements reflect the current expectations of the Company's management for future growth, results of operations, performance and business prospects and opportunities and involve significant known and unknown risks, uncertainties and assumptions, including, without limitation, those listed in the Company's Listing Statement and other filings made by the Company with the Canadian securities regulatory authorities (which may be viewed under the Company's profile at www.sedarplus.ca). Examples of forward-looking statements in this news release include, but are not limited to, statements regarding the proposed timeline and use of proceeds for exploration and development of the Company's mineral projects as described in the Company's Listing Statement, news releases, and corporate presentations. Should one or more of these risks or uncertainties materialize or should assumptions underlying the forward-looking statements prove incorrect, actual results, performance or achievements may vary materially from those expressed or implied by the forward-looking statements contained in this news release. These factors should be considered carefully, and prospective investors should not place undue reliance on the forward-looking statements. This list is not exhaustive of the factors that may affect any of the Company's forward-looking statements and reference should also be made to the Company's Listing Statement dated April 23, 2025 and news release dated May 16, 2025, and the documents incorporated by reference therein, filed under its SEDAR+ profile at www.sedarplus.ca for a description of additional risk factors. The Company disclaims any intention or obligation to revise forward-looking statements whether as a result of new information, future developments or otherwise, except as required by law.

i International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

ii International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

iii US Geological Survey (USGS). (2024). Mineral commodity summaries: Tungsten. Retrieved from https://pubs.usgs.gov/periodicals/mcs2024/mcs2024-tungsten.pdf

iv British Geological Survey (BGS). (2023). Tungsten fact sheet. Retrieved from https://www.bgs.ac.uk/downloads/start.cfm?id=1408

v Argus Media Group. (2025). Argus Tungsten Monthly Outlook. Issue 26-6, 11 June 2025. https://argusmedia.com

vi International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

vii International Tungsten Industry Association (ITIA). (2023). Tungsten: Global industry, markets & outlook. Retrieved from https://www.itia.info

To view the source version of this press release, please visit https://www.newsfilecorp.com/release/267656