- This stock has favourable risk-to-reward opportunity. QIMC currently has a nominal market cap of ~C$2.3M (~74 million shares trading near ~C$0.03).

- With quality proven high-purity silica assets, an operational pilot plant making custom orders for partnerships & offtake prospects, and a Right of First Refusal agreement with HPQ Silicon, it appears only a matter of time before QIMC gravitates significantly higher in share price (several multiples current).

Québec Innovative Materials Corp. (CSE: QIMC) (Frankfurt: 7FJ) (a.k.a. QI Materials) is a Canadian-based mineral exploration and development company that is executing on a strategy to become a sustainable supplier of resources which are essential in advanced batteries and the electrification of the green economy. QI Materials has a pilot silica processing plant, able to produce custom products to meet its partners specification. QI Materials has issued a 2024 strategy synopsis that rapidly advances it toward a near-term industrial mining production scenario on its portfolio of high-grade SiO2 properties in Ontario and Quebec (See related November 28, 2023 news release "Qi Materials Announces 2024 Strategy and Finalizes Right of First Refusal Agreement With HPQ Silicon Inc.")

QI Materials is always evaluating potential partnerships for all varying grades of its silica material and will be looking at offtake agreements in 2024.

Current noteworthy partnerships:

HPQ Silicon Inc. ("HPQ"): MOU signed regarding the procurement of Quartz from QI Material's Charlevoix Silica Project. Additionally, QI Materials has entered into a Right of First Refusal ("ROFR") agreement with HPQ which allows HPQ the ROFR to purchase the first 10,000 tons of high-grade silica material extracted from a QI Materials silica project.

Ekopav: MOU signed March 2023 regarding the procurement of silica sands for production of asphalt products.

Over the coming months QIMC will continue to provide silica feed from its Charlevoix project in Québec to various industry participants, while it juxtaposes development efforts to ready the River Valley project in Ontario and the new Charlevoix discovery zones. QI Materials continues to receive expressions of interest from various manufacturers globally (e.g. a representative from a private Chinese-owned company in the solar panel manufacturing industry recently visited the Company's facility in Lachute, Québec and was provided with samples for analysis at their lab in Vancouver, BC.).

QI Materials has announced the following plans and goals for 2024:

River Valley Silica Project, 65 Km northeast of Sudbury Ontario:

● Perform mechanical stripping of the quartz vein formation.

● Perform a hybrid detailed exploration/geotechnical drill program in order to delineate a resource and design the quarry.

● Execute quarry design and production plan.

● Conduct advanced metallurgical testing on silica material.

● Commence production permitting process.

● Negotiate strategic offtake agreements.

Note: River Valley has no permitting issues, it hosts a substantial quarryable body of 98% - 99.9+% pure SiO2 proximal roads and rail infrastructure. The River Valley Project is being advanced toward fast-track production (see related October 11, 2023 news release "QI Materials Procures OptiSim Mining Solutions for Engineering and Production Services").

Charlevoix Silica Project, Quebec:

● Secure bulk sample permit for Zones 1 and 2.

● Perform mechanical stripping on newly discovered zones 4, 5 and 6.

● Conduct exploration drilling on newly discovered zones 4, 5, and 6 to evaluate the size, geometry, depth, and width of the quartzite formation and determine if they are continuously connected to one another.

● Negotiate strategic offtake agreements.

The new discovery zones at Charlevoix are high-purity and are confirmed without permitting issues, 100% outside any hunting & fishing zec. Property zones will be stripped clean and various surveys conducted as needed with the intention of going operational; so far (as of the last update) zones 4 and 5 have been mapped in detail, cleaned off, channel sampled, and over 120m of strike length is now exposed at surface. The true thickness and width of the quartzite formation is currently unknown as the contacts are buried beneath overburden, however we can observe 5-10 metres high quartzite walls in certain areas. This October-2023 QI Materials announced that it has received a permit to further expand work on its high grade on surface Charlevoix Silica Project. It was an 8 month process and further expands the capacity to deliver even more high-grade material. This permitting is in line with the Québec government’s green supply chain strategy, and expands the QIMC’s operations and ability to deliver even more high-grade silica to clients who have been eagerly waiting for this.

Demand for reliable high-purity quartz/silica feed is increasingly critical for companies such as nearby Montreal-based HPQ Silicon Inc. which is developing several new advanced silicon innovation processes that will drive the future (see related news release "QI Materials Delivers Additional Samples to HPQ Silicon Inc." and "QIMC Contributes to HPQ Silicon Battery Initiative", among others), such as GM and Ford which are building new EV battery plants nearby (next gen lithium silicon anode batteries offer improved performance and capacity), such as solar panel glass manufactures and a myriad of other applications (ceramics, building materials, foundry and metals, coatings and polymers, chemicals, filtration and absorbents, etc.). CSE:QIMC is set for upside share price revaluation to better reflect its strategic positioning, able to provide crucial feed. Of particular note is the October 11, 2023 joint press release from HPQ Silicon and Pyrogenesis entitled "Successful Silicon Pour and Validation of All Critical Milestones in HPQ PUREVAP™ GEN3 QRR Testing" confirming continuous pour at scale of 2N+ silicon and achieving one-step 3N+ battery-grade silicon -- this technology is the future of silicon production. Also important to note is that quartz-derived silicon has gained significant strategic importance, recently earning a place on the USA's strategic mineral list.

WHY SILICA?

● Widely considered the next significant advance in battery technology.

● Cost effective.

● Sustainable mining with inert materials.

● Little waste – Applications for all grades.

● Most abundant element in earth’s crust after oxygen.

● Growing Global silica sand market ($11.2B in 2022 to ~$19B in 2029).

● New plants needed to meet demand growth.

Unlike traditional mining mineral resources (such as gold), which require copious amounts of drilling, silicon dioxide is industrial quartzite and a massive voluminous resource is able to be blocked out quickly with a few 100m drill holes (~1,000 m total should suffice), also these type of bodies are typically operated for multiple decades and the grades/quality get better with depth (where there is less weathering and impurities). The hard part (which QIMC has already accomplished) is to find the right combination of purity, consistency, access, permitting, and infrastructure -- the actual extraction of material is typically inexpensive (as its quarry-style mining), it is the transportation costs that can quickly add up. At River Valley its a short trip down the highway and onto established rail network, and at Charlevoix it is only ~3.5 hours by road to Montreal (where HPQ, and other manufacturers are along the Saint Lawrence). In-short, economics are expected to be robust.

Figure 1. (above) -- QIMC has various grades and types of feed stock, mined from its Charlevoix project, prepped and ready for delivery to clients requiring silica according to spec. Visible in the image above in the bags up front and in the insets are large crystalline-like chunks that are milled to specification; in HPQ Silicon Inc.'s case they are very specific: X size, at X grade, X-sort of dimension, roundness angularity, etc. -- reports are HPQ is very pleased with the product being delivered and explains why HPQ entered a ROFR agreement with QI Materials. In the image above, any weathered look is attributed to surface exposure -- simply crack below the surface and the silica is much more translucent white. The rows of bags further to the back are finer material, a by-product of processing the main batch -- this material would go to a different client such as an asphalt company; no waste.

Figure 2. (above) - Visual high purity quartz samples from River Valley Project quartz vein (source: October 24, 2023 corporate update news release).

Figure 3. (above) -- Aerial photograph of the Charlevoix Silica Project Main Zone 1.

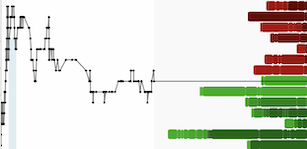

Figure 4. (above) -- QIMC's pilot mobile silica refining processing plant for custom batches, with inset of current world market pricing.

The following URLs have been identified for further DD on QI Materials:

- Company website: https://www.qimaterials.com

- Recent Mining MarketWatch Journal review: https://miningmarketwatch.net/qimc.htm

Content above may contain forward-looking statements regarding future events that involve risk and uncertainties. Readers are cautioned that these forward-looking statements are only predictions and may differ materially from actual events or results. Articles, excerpts, commentary and reviews herein are for information purposes and are not solicitations to buy or sell any of the securities mentioned.