$1.1 billion NPV (8%) • 19.0% IRR • 22 year mine life • Opportunities for exploration and optimization

February 4, 2021 – All figures in C$ unless otherwise noted

TSX Venture Exchange Symbol: NCX

Highlights

- The 2021 PEA confirms that the North Island Project is one of the most attractive copper-gold porphyry projects in Canada:

- Long mine life of 22 years with average annual production of 177 mm lbs Cu Eq. over the first 6 years, including 112 mm lbs of copper, 112 koz of gold and 2.7mm lbs of molybdenum

- Average annual after tax free cash flow of $321 million during the first 6 years and $224 million over the life of the operation

- First quartile AISC of $0.77/lb Cu (net of by-products) and $2.01/lb Cu Eq. over first 6 years

- Attractive economics with $1.1 billion After-tax NPV (8%) and 19% After-tax IRR

- Attractive payback of 3.9 years driven by modest capex of $1.4 billion due to excellent infrastructure from historical mining and other industrial activity

- Northisle is committed to sustainable mine development:

- Northisle will pursue a collaborative, inclusive approach to consultation in order to develop a project which creates benefits for First Nations, local communities, shareholders and project stakeholders

- The Project benefits from renewable BC power and the Company will investigate multiple opportunities to reduce overall impact including electrified mining operations as part of trade-off studies

- Multiple opportunities to further improve the Project through optimization and exploration with prospective targets at Pemberton Hills, Red Dog and Hushamu planned for 2021 drilling

VANCOUVER, BC, Feb. 4, 2021 /CNW/ - Northisle Copper and Gold Inc. (TSXV: NCX) ("Northisle" or the "Company") is pleased to announce that the positive results from a Preliminary Economic Assessment (the "2021 PEA") for its 100% owned North Island Project confirm it is one of the most attractive copper-gold porphyry projects in Canada.

The 2021 PEA is based on the Company's 100% owned Red Dog and Hushamu deposits and has been developed with a focus on processing a target of 600MT of mineralized material within estimated mineable pit shells. The PEA contemplates a low strip ratio open pit mining operation which incorporates a 75,000 t/d concentrator and is anticipated to produce a high-quality copper concentrate with a significant gold by-product as well as a high-grade molybdenum concentrate.

Key performance indicators are summarized in Table 1 below.

Table 1: Summary Project Metrics | ||||||||||

Production | AISC | After-tax Avg. | After-tax | After- | GHG Emissions | |||||

Cu (mm lbs) | Au (koz) | Cu Eq. (mm lbs) | Cu | Cu Eq. | $ mm | $ mm | % | Cu | Cu Eq. | |

First 6 years average | 112.1 | 111.8 | 177.5 | $0.77 | $2.01 | 321 | 1,059 | 19.0 | 0.66 | 0.41 |

Life of mine ("LOM") average | 95.9 | 99.9 | 155.9 | $0.90 | $2.14 | 224 | ||||

Note: Cu Eq. based on Base Case metal prices and includes molybdenum and rhenium. See Table 3 for details. |

Sam Lee, President and CEO of Northisle commented, "I am delighted with the progress we have made in demonstrating that the North Island Project is one of the most attractive copper and gold development projects today. The 2021 PEA illustrates a significant improvement in the potential of the North Island Project. Copper and gold production increased materially resulting in a significant increase in NPV and IRR, while all-in sustaining costs remain in the first quartile and initial capital is modest for a long-life and significant copper and gold asset. The concentrate planned to be produced by the North Island Project is anticipated to be a premium product which would be highly attractive to global smelters. Furthermore, the significant gold production is anticipated to provide several options for lower cost capital financings. We are excited to be advancing what we believe is one of the most attractive Canadian copper projects during the start of a new mining super cycle.

There exists a multitude of opportunities to develop a mine that is truly sustainable in all respects. We are excited to continue our consultation work with First Nations, local communities, governments, and key project stakeholders as we advance this important and compelling project. We have direct access to clean power in British Columbia that will drive our project towards becoming a lower carbon emissions operation. Over the coming months, we will continue to optimize key project parameters to create additional value for shareholders while focusing on reducing the impact of the North Island Project.

Exploration activities will also be reactivated in 2021 with an initial drill program focusing on three main areas: Red Dog, Pemberton Hills, and Hushamu. Program objectives include increasing tonnage and grade for the North Island Project, confirming the existence of a larger, higher grade copper-gold porphyry system at Pemberton Hills, and exploring multiple targets over our vast 33,000 ha property.

Our leadership team is fully committed to realizing our vision of making Northisle Canada's leading sustainable resource development company."

The Company will host a conference call and webcast on Thursday, February 4, 2021 at 11:00 AM Eastern time (8:00 AM Pacific time). Details to access the call can be found below.

2021 PEA Summary

The 2021 PEA was prepared in accordance with National Instrument 43-101 ("NI43-101") by M3 Engineering & Technology Corp. ("M3") in conjunction with an updated mine plan prepared by John Nilsson, an updated Mine Waste Facility ("MWF") design prepared by Golder Associates Ltd. (Golder) and updated metallurgical testwork performance by SGS Canada Inc. ("SGS"). The team was led by Cam Brown, P. Eng. (Nova Scotia) on behalf of Northisle. The Company plans to file the complete 2021 PEA report on SEDAR at www.sedar.com within 45 days of this press release. The 2021 PEA updates the previously published study on the North Island Project, titled "North Island Copper and Gold Project, NI43-101 Technical Report, Preliminary Economic Assessment" and dated October 24, 2017 (the "2017 PEA"). Table 2 summarizes the key findings of the 2021 PEA.

Table 2: 2021 PEA Economic Highlights | |||

Base Case Economics | Units | Pre-tax | After-tax |

Net Present Value (NPV 8%) | $ millions | 1,494 | 1,059 |

Net Present Value (NPV 8%) | US$ millions | 1,121 | 795 |

Internal Rate of Return | % | 21.7% | 19.0% |

Payback | Years | 3.9 | 3.9 |

Initial Capital Cost | $ millions | 1,442 | |

Sustaining Capital Cost | $ millions | 197 | |

Economic Assumptions | Units | Base Case | |

Copper | US$/lb | $3.25 | |

Gold | US$/oz | $1,650 | |

Molybdenum | US$/lb | $10.00 | |

Rhenium | US$/kg | $1,256 | |

CAD:USD Exchange Rate | US$/C$ | 0.75 | |

Financial Metrics | Units | First 6 years | LOM |

Average Annual Revenue | $ millions | 740 | 649 |

Average Annual Operating Costs | $ millions | 340 | 301 |

Avg. Ann. Free Cash Flow (after tax) | $ millions | 321 | 224 |

The 2021 PEA is preliminary in nature and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would enable them to be categorized as mineral reserves. There is no certainty that the project described in the 2021 PEA will be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

Table 3 provides a summary of the key operating metrics from the 2021 PEA.

Table 3: 2021 PEA Operating Highlights | ||||

Operating Statistics | Units | Avg. First 6 years | Avg. LOM | |

Mine Life | Years | 22 | ||

Tonnes Processed | KT | 27,060 | 27,289 | |

Strip Ratio | W:O | 1.04 | 0.71 | |

Production | ||||

Copper | mm lbs | 112.1 | 95.9 | |

Gold | koz | 111.8 | 99.9 | |

Molybdenum | klbs | 2,726 | 2,954 | |

Cu Eq. | mm lbs | 177.5 | 155.9 | |

Cash Cost – Cu with by-products | $/lb | $0.75 | $0.81 | |

Cash Cost – Cu Eq | $/lb | $2.00 | $2.09 | |

AISC – Cu with by-products | $/lb | $0.77 | $0.90 | |

AISC – Cu Eq | $/lb | $2.01 | $2.14 | |

By-products and Cu Eq. calculated at Base Case metal prices |

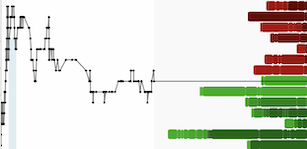

Economic Sensitivity

Table 4 summarizes the after-tax sensitivities of NPV and IRR to metal prices.

Table 4: Economic Sensitivity to Metal Prices | ||||

Metal Prices | After- tax NPV (5%) $ millions | After-tax NPV (8%) $ millions | After-tax NPV (10%) $ millions | IRR (%) |

Spot Prices1 | $2,116.4 | $1,396.1 | $1,049.0 | 22.3% |

Base Case + 20% | $2,682.7 | $1,833.7 | $1,425.0 | 26.5% |

Base Case + 10% | $2,182.6 | $1,447.2 | $1,092.9 | 22.8% |

Base Case | $1,682.5 | $1,059.4 | $759.1 | 19.0% |

Base Case – 10% | $1,180.2 | $666.8 | $419.3 | 15.0% |

Base Case – 20% | $674.1 | $265.4 | $68.9 | 10.8% |

Note: Economic assumptions are detailed in Table 14 |

1. Spot prices as of February 2, 2021. |

Sustainability

Northisle intends to integrate a sustainable approach to mine development into every part of its corporate culture. This means that monitoring, disclosing, and improving on ESG performance is as critical as operating metrics. As a result, Northisle has summarized preliminary sustainability metrics for the North Island Project in Table 5 below.

Table 5: Preliminary Sustainability Metrics | ||

Sustainability Statistics | Units | LOM Total / Avg. |

Direct local job creation (permanent) | FTE | 450 |

Site Energy Consumption | ||

Fuel (annual) | 000s liters | 21,000 |

Electricity (annual) | MWh | 794,000 |

Energy Intensity | kWh/lb Cu | 10.5 |

Environmental | ||

Net water consumption | liters / lb Cu | 99.6 |

GHG Emissions – Scope 1 | kg CO2e / lb Cu | 0.66 |

Total Material to MWF | MT | 1,020 |

The above sustainability metrics were determined on a preliminary basis by referencing publicly available benchmarks for emissions related to key project energy sources. The selected metrics will evolve as the project is developed, to incorporate additional measures of ESG performance.

Opportunities

The PEA demonstrates the potential for further development of the North Island Project and indicates a number of additional opportunities for further study which may contribute to further enhanced value, including:

- Evaluate the opportunity for sale of pyrite concentrate: Preliminary study and test work indicates that a substantial quantity of high-grade pyrite concentrate can be recovered. Additional studies are required to determine the marketability of pyrite concentrate.

- Consider use of historical Island Copper Pit for mine tailings storage: The existing pit at the former BHP Island Copper Operation could potentially be re-purposed to store most of the tailings from the North Island Project development, which represents an opportunity to reduce the risk profile for the project.

- Trolley-assisted haulage: The current project uses electrical power for the mining shovels and drills at Hushamu and an opportunity exists to consider trolley-assisted haulage to reduce emissions from the proposed diesel-electric fleet.

- Reduce carbon emissions: Northisle will conduct an energy audit to evaluate available technologies and best practices to drive the project development towards attaining carbon emission reduction goals.

- Metallurgical optimization: Future test work will target improved recoveries, refined reagent regimes, optimization of grind versus recovery in both primary and regrind circuit to drive lower energy and media consumption while maintaining mineral recovery effectiveness.

- Engineering trade-off studies: Conduct engineering trade-off studies to improve plant performance, reduce operating and maintenance cost and enhance on-line availability as well as opportunities to optimize plant throughput.

Next Steps

With the completion of the 2021 PEA, Northisle intends to continue to advance the North Island Project. Key next steps and milestones include:

- Commencement of planned 2021 drill program which will include exploration drilling at Pemberton Hills, Red Dog and NW Expo, as well as in fill and step-out drilling at Hushamu

- Additional extensive surface mapping and sampling of several additional prospective porphyry targets (H2)

- Commencement of critical trade-off studies, environmental baseline work and other long-lead items in support of determining the scope of a pre-feasibility study in H2 2021.

- Northisle will continue to proactively engage with First Nations, local communities, government and key project stakeholders in support of the responsible development of the project.

Webcast Details

The Company will host a conference call on Thursday, February 4, 2021 at 11:00 AM Eastern time (8:00 AM Pacific time). Details to access the call live are as follows:

- Via telephone, toll free, by calling 1-416-764-8659 in Toronto or internationally, 1-778-383-7413 in Vancouver and 1-888-664-6392 toll free in North America

- Via webcast at: Webcast

The webcast will be archived for 365 days following the call at the above-noted link and on the Company's website. The conference call will also be available for replay until Thursday, February 11, 2021. To access the replay, dial 1-416-764-7677 or 1-888-390-0541 and use Playback Passcode 784988# to hear the recording.

2021 PEA Details

The 2021 represents an update of the 2017 PEA, with the primary changes including updated recoveries, metal prices, operating and capital costs, and an updated mine plan. The study was prepared independently by M3 and incorporates results from independent metallurgical testing by SGS and MWF design by Golder, and mine plan developed by John Nilsson. The Company now intends to commence important work to prepare for initiation of a pre-feasibility study, while accelerating the exploration program throughout the property.

Mineral Resources

Mineral Resources for the Hushamu deposit were updated for the purpose of the 2021 PEA by incorporating 5 drill holes completed in 2017 which had not been incorporated in earlier estimates. These drill holes had the anticipated impact of converting several Inferred blocks into the Indicated category. In addition, the cut-off grade for the resource was revised to 0.10% which had the result of increasing tonnage in both Indicated and Inferred Resources while reducing grade.

Table 6: Combined Summary Resource Estimate | |||||

Category | Tonnes | % Cu | g/t Au | % Mo | g/t Re |

Indicated | |||||

Hushamu | 472,854,000 | 0.20% | 0.23 | 0.008% | 0.35 |

Red Dog | 54,490,000 | 0.22% | 0.31 | 0.004% | * |

Total Indicated | 527,344,000 | 0.20% | 0.24 | 0.008% | 0.31 |

Inferred | |||||

Hushamu | 414,293,000 | 0.15% | 0.18 | 0.006% | 0.29 |

Red Dog | 2,979,000 | 0.17% | 0.25 | 0.002% | * |

Total Inferred | 417,272,000 | 0.15% | 0.18 | 0.006% | 0.29 |

Note: Resources shown at a 0.10% Cu cut-off grade. |

A complete summary of mineral resources can be found at the end of this release.

Mining

Preliminary mine designs have been developed for Red Dog and Hushamu deposits based upon Indicated and Inferred Resources. Resource models were imported to Minesight® mine planning software where a Lerchs Grossman algorithm was applied to an NSR model to determine possible pit limits.

The mine plan was developed to mine Red Dog concurrently with Hushamu in the early years of the mine life until Red Dog Resources were depleted. The assumed processing rate is 75,000 t/d; Red Dog contributes 24,000 t/d while in operation. The overall mining rate peaks at 64 million t/a in the initial years averaging 47 million t/a over the total mine life of 22 years. The effective strip ratio after stockpile reclaim was 0.71:1.

The mine is planned to be a conventional truck and shovel operation with electrified pit operations at Hushamu. Waste rock will be placed during construction and operation within the MWF. A low-grade stockpile will be located at the pit rim on the northwest side of Hushamu. An overburden stockpile will be located adjacent to the low-grade stockpile for use in reclamation of the MWF at the end of the mine life.

Table 7: Key mining statistics | ||

Metric | Units | Quantity |

Mine life | Years | 22 |

Milling rate | t/d | 75,000 |

Strip Ratio | W:O | 0.71 |

Total Tonnage Mined | MT | 1,032.3 |

Total Mineralized Material Mined | MT | 602.3 |

LOM Average Grades | ||

Copper | % | 0.18% |

Gold | g/t | 0.24 |

Molybdenum | % | 0.008% |

The total resources processed in the conceptual mine plan are shown in the following tables. The quantity of mineralized material was estimated and included in the mine plan using an NSR threshold approach, rather than a copper cut-off grade. The Hushamu Leached Zone (denoted LEA in Table 15 and Table 16) is excluded from the 2021 PEA mine plan. Tonnages in the mine plan are summarized in Table 8 and Table 9 while mine operating costs are summarized in Table 10.

Table 8: Indicated Mineral Resources Included in the Mine Plan | |||||

Indicated Resources | ROM t x 1000 | Cu (%) | Au (g/t) | Mo (%) | NSR ($/t) |

Hushamu Starter Pit | 83,530 | 0.24 | 0.27 | 0.007 | 22.76 |

Hushamu Phase 1 Expansion | 96273 | 0.20 | 0.19 | 0.007 | 17.68 |

Hushamu Phase 1.5 Expansion | 126,312 | 0.18 | 0.27 | 0.011 | 18.33 |

Hushamu Phase 2 Expansion | 115,483 | 0.17 | 0.25 | 0.008 | 17.77 |

Red Dog | 50,885 | 0.22 | 0.32 | 0.005 | 24.82 |

Total | 472,483 | 0.20 | 0.25 | 0.008 | 19.54 |

Table 9: Inferred Mineral Resources Included in the Mine Plan | |||||

Inferred Resources | ROM t x 1000 | Cu (%) | Au (g/t) | Mo (%) | NSR ($/t) |

Hushamu Starter Pit | 2,973 | 0.12 | 0.15 | 0.016 | 11.40 |

Hushamu Phase 1 Expansion | 13,068 | 0.13 | 0.13 | 0.010 | 11.64 |

Hushamu Phase 1.5 Expansion | 35,037 | 0.14 | 0.23 | 0.012 | 15.00 |

Hushamu Phase 2 Expansion | 76,598 | 0.14 | 0.20 | 0.007 | 14.44 |

Red Dog | 2,172 | 0.17 | 0.27 | 0.003 | 19.91 |

Total | 129,848 | 0.14 | 0.20 | 0.009 | 14.33 |

Table 10: Mining Costs | |

Area | Unit Cost (C$/t mined) |

Drilling | 0.13 |

Blasting | 0.35 |

Loading | 0.24 |

Hauling | 0.69 |

Support | 0.49 |

Mine General | 0.21 |

Total Mining Cost excl. equipment lease | 2.11 |

Mine equipment lease | 0.21 |

Note: totals may not add due to rounding |

Processing

The 2021 PEA contemplates a concentrator and related facilities processing mineralized material at a nominal rate of 75,000 t/d through a grinding circuit comprised of a single SAG mill and two ball mills, flotation facilities and regrind facilities to recover copper and molybdenum concentrates for export. Gold reports primarily to the copper concentrate while rhenium reports primarily to the molybdenum concentrate. Processing costs are summarized in Table 11.

Table 11: Processing Costs | |

Area | Unit Cost (C$/t processed) |

Salaries & Wages | 0.50 |

Power | 1.84 |

Liners | 0.36 |

Grinding Media | 1.03 |

Reagents | 1.20 |

Maintenance Parts & Repairs | 0.48 |

Supplies & Services | 0.10 |

Total Processing Cost | 5.52 |

Metallurgy

Additional metallurgical test work was undertaken in 2020 by SGS to target better recoveries of the principal minerals. M3 reviewed and interpreted the test work and incorporated the results into the process plant design criteria, flowsheet development, and process equipment selection. The design basis for the processing plant is 75,000 t/d or 27,375,000 t/a at 93% availability. Design mineral grades to the process plant are estimated at 0.18% copper, 0.24 g/t gold and 0.008% molybdenum with overall estimated recoveries of approximately 86.4% for copper, 46.8% for gold, and 59.5% for molybdenum.

Operating Cost Summary

A preliminary operating cost estimate was prepared for the North Island Project based on a 75,000 t/d mine/mill operation. Total site operating costs are summarized in Table 12.

Table 12: Total Site Operating Costs | ||

Area | Units | Cost |

Mining Cost1 | $/tonne processed | $3.84 |

Processing | $/tonne processed | $5.52 |

G&A | $/tonne processed | $0.38 |

Water Treatment | $/tonne processed | $0.06 |

Total Site Operating Costs | $/tonne processed | $9.81 |

1. Including leased mining equipment |

Capital Cost and Infrastructure Summary

The capital cost estimate was developed by M3 using an EPCM project development approach. Golder developed a conceptual design for the MWF and provided estimated quantities of construction material required to construct the facility. M3 then estimated the associated initial and sustaining capital cost based on the quantities provided. The mine plan and associated mine initial and sustaining capital was prepared by John Nilsson using current equipment prices and leasing terms & conditions provided by the mine equipment procurement consultant retained by Northisle. The process facilities and other related facilities were designed and estimated by M3. The capital cost of these facilities was developed using budgetary quotes obtained for major process and infrastructure facility equipment requirements, and construction labour rates obtained from a BC contractor experienced in the scope and scale of the North Island Project. The 2021 PEA capital cost estimate is summarized in Table 13 below.

Table 13: Capital Cost Summary | |

Area | $ million |

Mine1 | 17.8 |

Pre-production | 130.9 |

Process | 1,235.4 |

Owner's Cost | 57.9 |

Total | 1,442.0 |

1. Mine equipment is included primarily on a leased basis in the financial model. |

The nearby town of Port Hardy is a main distribution centre for the north end of Vancouver Island. It has an airport with regular flights to Vancouver, a hospital, schools, and a college. The North Island Project is generally accessible for exploration purposes from Port Hardy through a network of logging roads.

BHP is in the process of reclaiming its historical marine load out infrastructure from its past-producing Island Copper Mine. The 2021 PEA contemplates the construction of a new marine load-out facility on the reclaimed site, which would be used to load concentrate onto ocean-going vessels for shipment to smelters in Asia. One of BC's largest wind farm complexes is situated adjacent to the northwest end of the property and the 138 KV power line connecting the wind farm to the main BC power grid passes immediately north of the North Island Project. The 2021 PEA contemplates connecting to the BC Hydro grid via the existing main substation near the highway into Port Hardy.

Economic Analysis

Economic evaluations were generated incorporating forecasts for economic inputs using the Base Case and Spot Price. The spot price case is based on prices as of February 2, 2021. See Table 14 for the results of the economic analysis.

Table 14: Economic Analysis | |||

Parameter | Unit | Base Case | Spot Price1 |

Copper Price | US$/lb | $3.25 | $3.51 |

Gold Price | US$/oz | $1,650.00 | $1,835.60 |

Molybdenum Price | US$/lb | $10.00 | $10.03 |

Rhenium Price | US$/kg | $1,256.00 | $1,256.00 |

CAD:USD Exchange rate | US$/C$ | 0.75 | 0.75 |

Average Annual Revenue | $ million | $648.6 | $704.9 |

Economic Result (before tax) | |||

Avg. Free Cash Flow | $ million | $277.1 | $321.2 |

NPV (5%) | $ million | $2,296.9 | $2,871.8 |

NPV (8%) | $ million | $1,494.3 | $1,937.3 |

NPV (10%) | $ million | $1,109.9 | $1,489.6 |

IRR | % | 21.7% | 25.5% |

Payback | Years | 3.9 | 3.4 |

Economic Result (after tax) | |||

Avg. Free Cash Flow | $ million | $223.6 | $256.7 |

NPV (5%) | $ million | $1,682.5 | $2,116.4 |

NPV (8%) | $ million | $1,059.4 | $1,396.1 |

NPV (10%) | $ million | $759.1 | $1,049.0 |

IRR | % | 19.0% | 22.3% |

Payback | Years | 3.9 | 3.5 |

The 2021 PEA is preliminary in nature and includes inferred mineral resources that are considered too speculative geologically to have the economic considerations applied to them that would allow them to be categorized as mineral reserves and there is no certainty that the preliminary economic assessment will be realized. Mineral resources that are not mineral reserves do not have demonstrated economic viability.

Technical Report and Qualified Persons

A National Instrument 43-101 (NI 43-101) compliant technical report entitled "North Island Project PEA" prepared by the following Qualified Persons will be filed by the Company within 45 days of this release on www.sedar.com:

- Laurie Tahija, MMSA – M3 Engineering – Recovery Methods and Process Operating Costs

- Daniel Roth, P.Eng. – M3 Engineering – Project Plant and Infrastructure Costs, Economic Analysis

- Brian Game, P. Geo. – Principal of GeoMinEx Consultants – Geology, Exploration and Environmental

- Phil Burt, P. Geo. – CEO of Burt Consulting Services – Mineral Resource Estimates

- John Nilsson, P. Eng. – Mining Methods

- Ben Wickland, P.Eng. of Golder Associates Ltd. – Mine Waste Facility

The Qualified Persons have reviewed and approved the scientific, technical, and economic information obtained in this news release.

About Northisle

Northisle Copper and Gold Inc. is a Vancouver based company whose mission is to become Canada's leading sustainable mineral resource company for the future. Northisle owns the North Island Project, which is one of the most promising copper and gold porphyry deposits in Canada. The North Island Project is located near Port Hardy, British Columbia on a 33,149-hectare block of mineral titles 100% owned by Northisle stretching 50 kilometres northwest from the now closed Island Copper Mine operated by BHP Billiton. The Company recently completed a preliminary economic assessment which demonstrated the potential of the Red Dog and Hushamu deposits and is aggressively advancing its exploration and development program in 2021.

For more information on Northisle please visit the Company's website at www.northisle.ca.

On behalf of Northisle Copper and Gold Inc.

Nicholas Van Dyk, CFA

Vice President, Corporate Development and Investor Relations

Tel: (778) 655-9582

Email: info@northisle.ca

www.northisle.ca

This news release does not constitute an offer to sell or a solicitation of an offer to buy any of the securities in the United States. The securities have not been and will not be registered under the United States Securities Act of 1933, as amended (the "U.S. Securities Act") or any state securities laws and may not be offered or sold within the United States or to U.S. Persons unless registered under the U.S. Securities Act and applicable state securities laws or an exemption from such registration is available.

Cautionary Statements regarding Forward-Looking Information

Certain information in this news release constitutes forward-looking statements under applicable securities law. Any statements that are contained in this news release that are not statements of historical fact may be deemed to be forward-looking statements. Forward-looking statements are often identified by terms such as "may", "should", "anticipate", "expect", "intend" and similar expressions. Forward-looking statements in this news release include, but are not limited to, statements relating to the anticipated timing of the 2021 PEA, anticipated 2021 PEA results, anticipated 2021 activities, the Company's plans for advancement of the North Island Project, including the potential use of existing infrastructure, expectations regarding the 2021 drill program; the Company's plans for engagement with Indigenous nations, communities and key stakeholders, and the Company's anticipated exploration activities. Forward-looking statements necessarily involve known and unknown risks, including, without limitation, Northisle's ability to implement its business strategies; risks associated with mineral exploration and production; risks associated with general economic conditions; adverse industry events; stakeholder engagement; marketing and transportation costs; loss of markets; volatility of commodity prices; inability to access sufficient capital from internal and external sources, and/or inability to access sufficient capital on favourable terms; industry and government regulation; changes in legislation, income tax and regulatory matters; competition; currency and interest rate fluctuations; and other risks. Readers are cautioned that the foregoing list is not exhaustive.

Readers are further cautioned not to place undue reliance on forward-looking statements as there can be no assurance that the plans, intentions or expectations upon which they are placed will occur. Such information, although considered reasonable by management at the time of preparation, may prove to be incorrect and actual results may differ materially from those anticipated. Forward-looking statements contained in this news release are expressly qualified by this cautionary statement.

The forward-looking statements contained in this news release represent the expectations of management of Northisle as of the date of this news release, and, accordingly, are subject to change after such date. Northisle does not undertake any obligation to update or revise any forward-looking statements, whether as a result of new information, future events or otherwise, except as expressly required by applicable securities law.

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this news release.

Table 15: 2021 Hushamu Resource Estimate – Indicated Resource | |||||

Mineral Domain | Tonnes | % Cu | g/t Au | % Mo | g/t Re |

LEA | 8,843,000 | 0.14 | 0.22 | 0.008 | 0.29 |

CMG-SCP-PRO | 462,475,000 | 0.20 | 0.24 | 0.008 | 0.35 |

QFP | 1,536,000 | 0.11 | 0.08 | 0.004 | 0.03 |

Total Indicated Resource | 472,854,000 | 0.20 | 0.23 | 0.008 | 0.35 |

1. | Tonnages have been rounded to the nearest 1,000 tonnes so may not add up. |

2. | Classification is compliant with the "CIM Resource Definition Standards, 2014" |

3. | It is assumed that with continued exploration, most of the Inferred Resource could be upgraded to an Indicated Resource category. |

Note: Resources shown at a 0.10% Cu cut-off grade. | |

Table 16: 2021 Hushamu Resource Estimate – Inferred Resource | |||||

Mineral Domain | Tonnes | % Cu | g/t Au | % Mo | g/t Re |

LEA | 2,169,000 | 0.13 | 0.18 | 0.008 | 0.26 |

CMG-SCP-PRO | 410,265,000 | 0.15 | 0.18 | 0.006 | 0.30 |

QFP | 1,859,000 | 0.12 | 0.10 | 0.005 | 0.15 |

Total Inferred Resources | 414,293,000 | 0.15 | 0.18 | 0.006 | 0.29 |

1. | Tonnages have been rounded to the nearest 1,000 tonnes so may not add up. |

2. | Classification is compliant with the "CIM Resource Definition Standards, 2014" |

3. | It is assumed that with continued Exploration, most of the Inferred Resource could be upgraded to an Indicated Resource category. |

Note: Resources shown at a 0.10% Cu cut-off grade. | |

Table 17: 2017 Red Dog Resource Summary | ||||

Tonnes | % Cu | g/t Au | % Mo | |

Indicated Resource | 54,490,000 | 0.22 | 0.31 | 0.004 |

Inferred Resource | 2,979,000 | 0.17 | 0.25 | 0.002 |

Game, B. and Burt, P. 2017 |

Note: Resources shown at a 0.10% Cu cut-off grade. |

![]() View original content to download multimedia:http://www.prnewswire.com/news-releases/northisle-announces-positive-pea-for-the-north-island-project-which-confirms-it-is-one-of-the-most-attractive-cu-au-projects-in-canada-301221887.html

View original content to download multimedia:http://www.prnewswire.com/news-releases/northisle-announces-positive-pea-for-the-north-island-project-which-confirms-it-is-one-of-the-most-attractive-cu-au-projects-in-canada-301221887.html

SOURCE NorthIsle Copper and Gold Inc.

![]() View original content to download multimedia: http://www.newswire.ca/en/releases/archive/February2021/04/c5489.html

View original content to download multimedia: http://www.newswire.ca/en/releases/archive/February2021/04/c5489.html